Flexible 3d Printed Parts

3d printing with flexible materials can really expand the capabilities of any project.

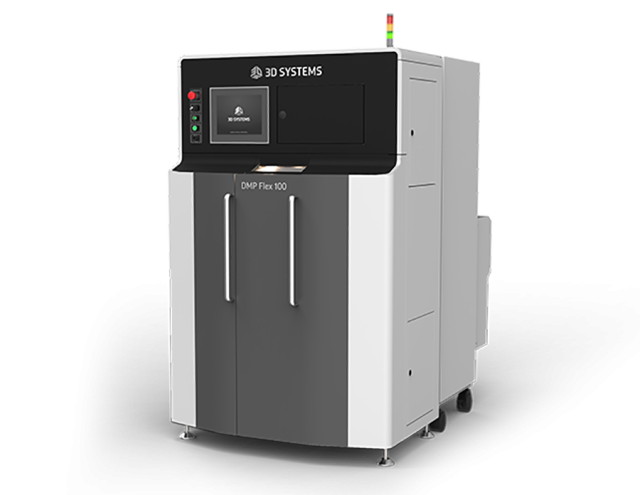

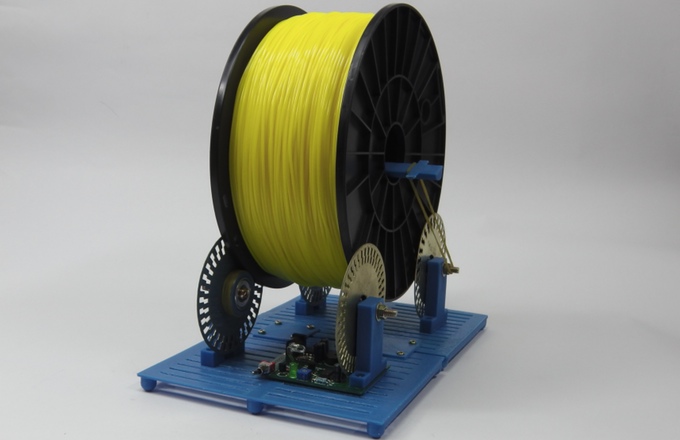

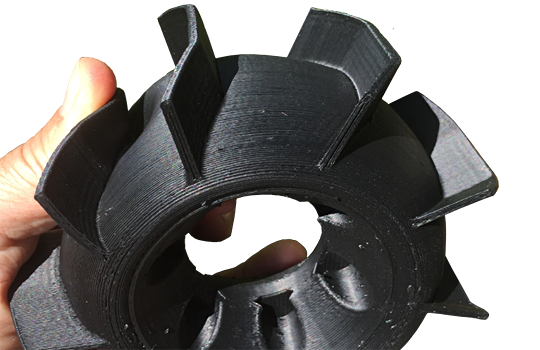

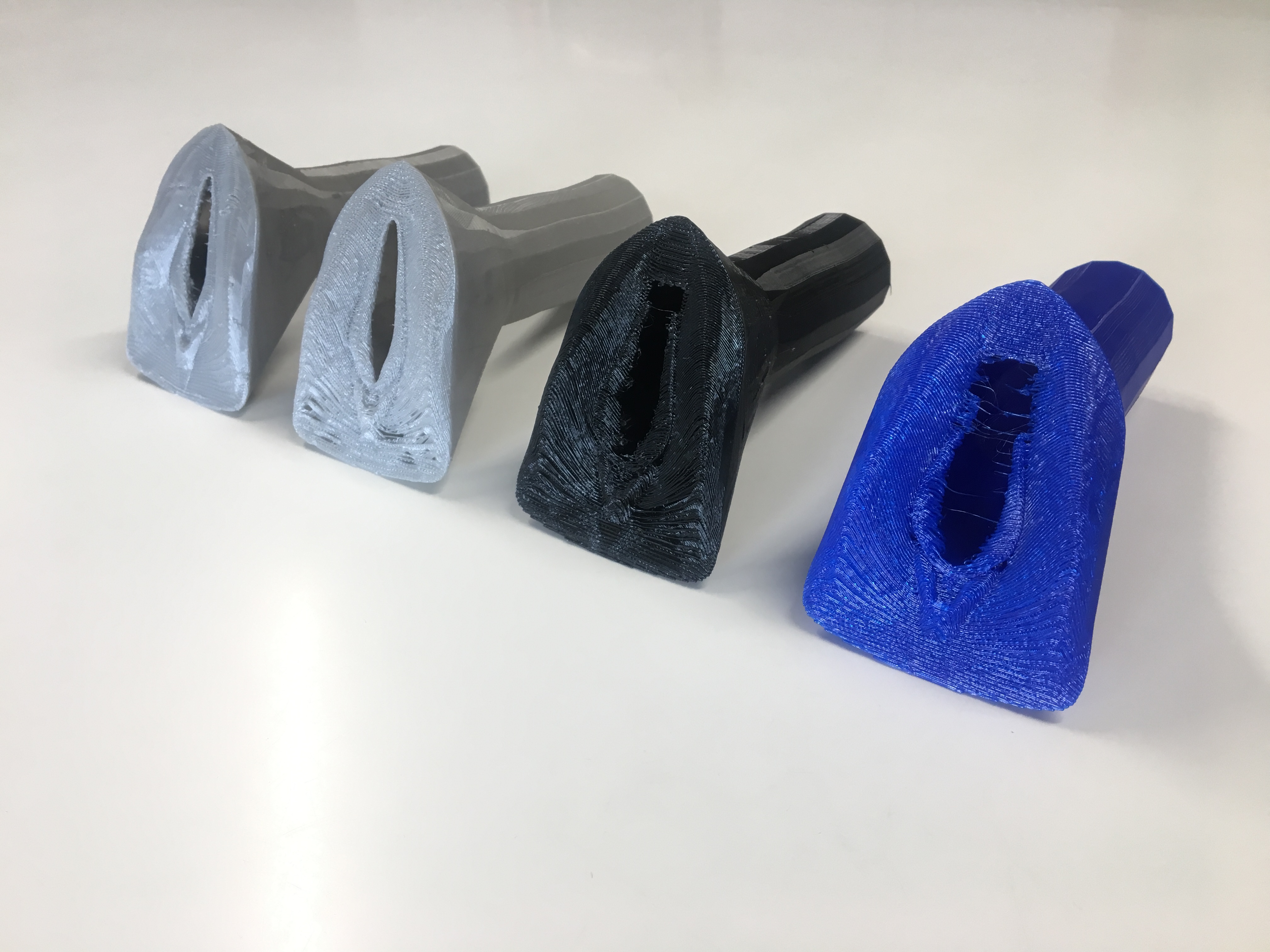

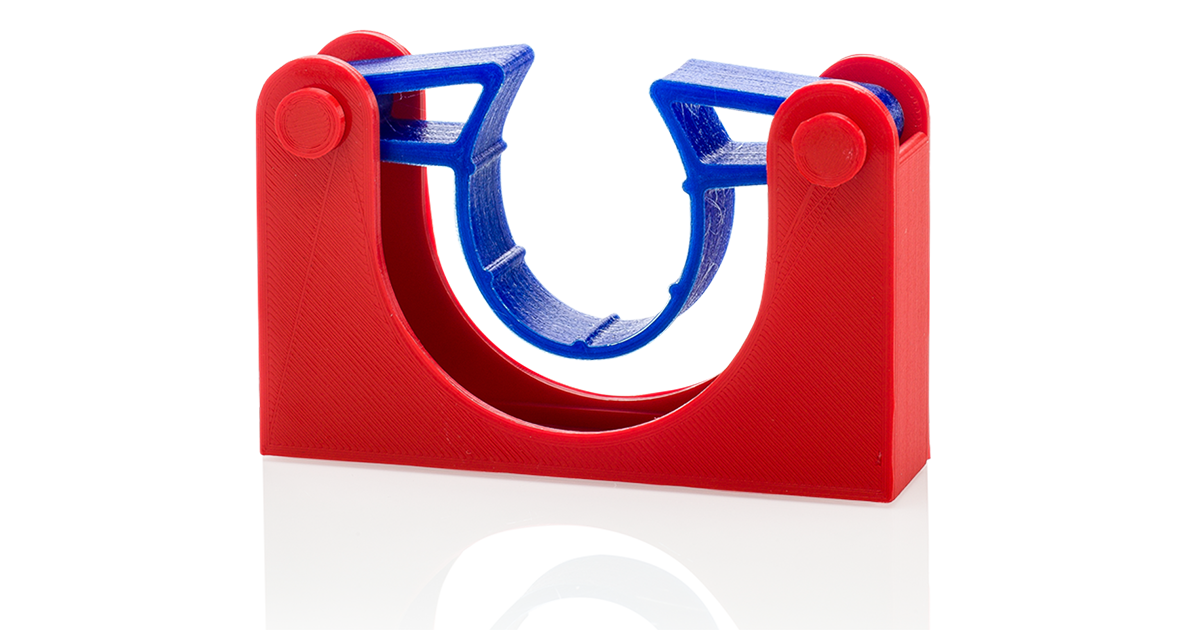

Flexible 3d printed parts. You can use special flexible filaments in regular fdm 3d printers to make elastic 3d printed parts. Polyjet is an industrial 3d printing process that builds multi material prototypes with flexible features and complex parts with intricate geometries in as fast as 1 day. Formerly the go to material for flexible 3d printing tpe is a very soft rubber like plastic that can be bent or stretched without deformation. Need enhanced precision for 3d printed parts.

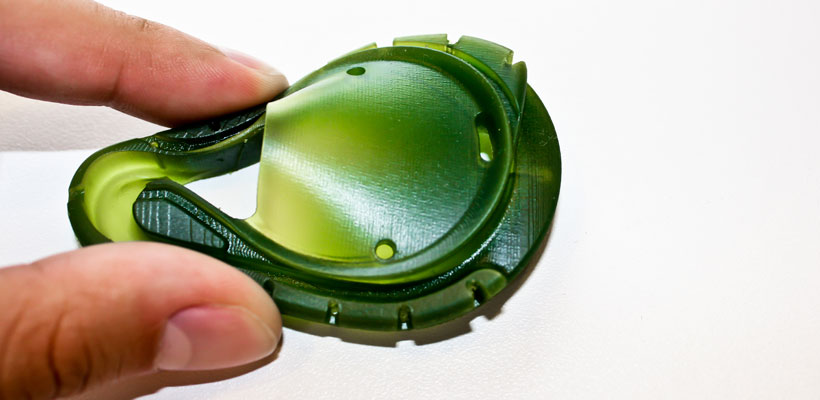

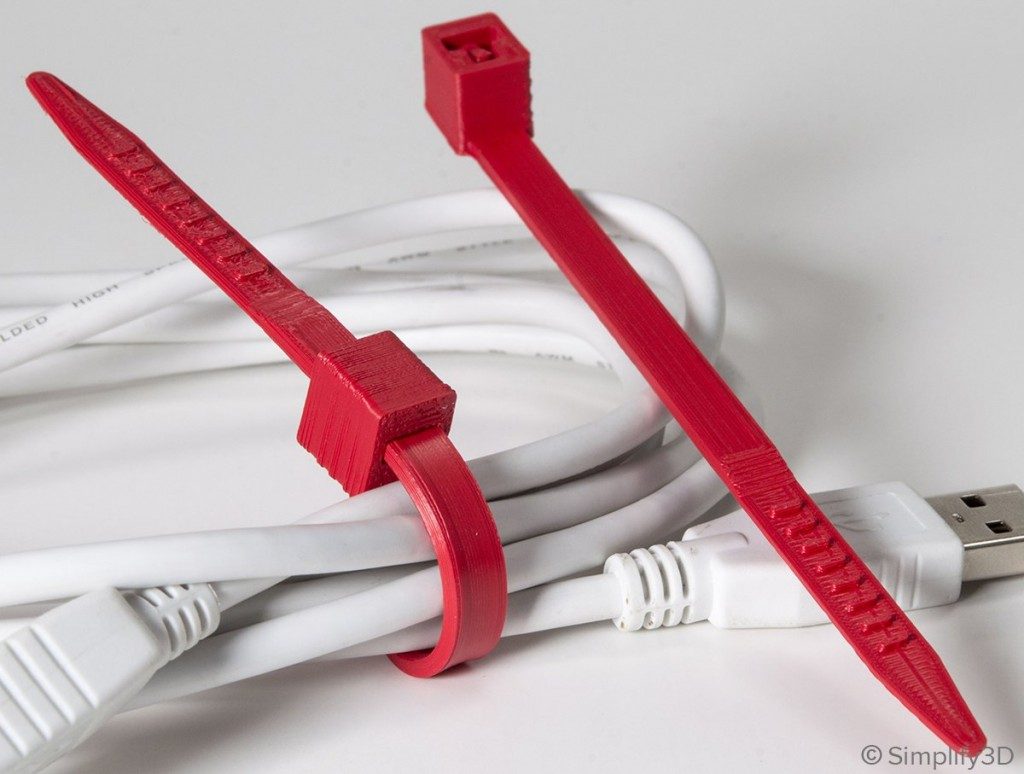

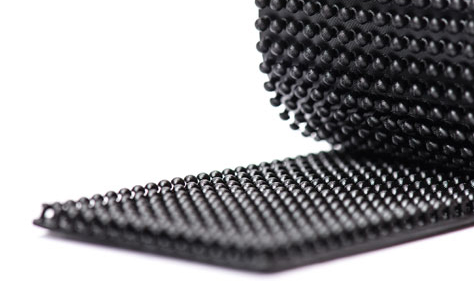

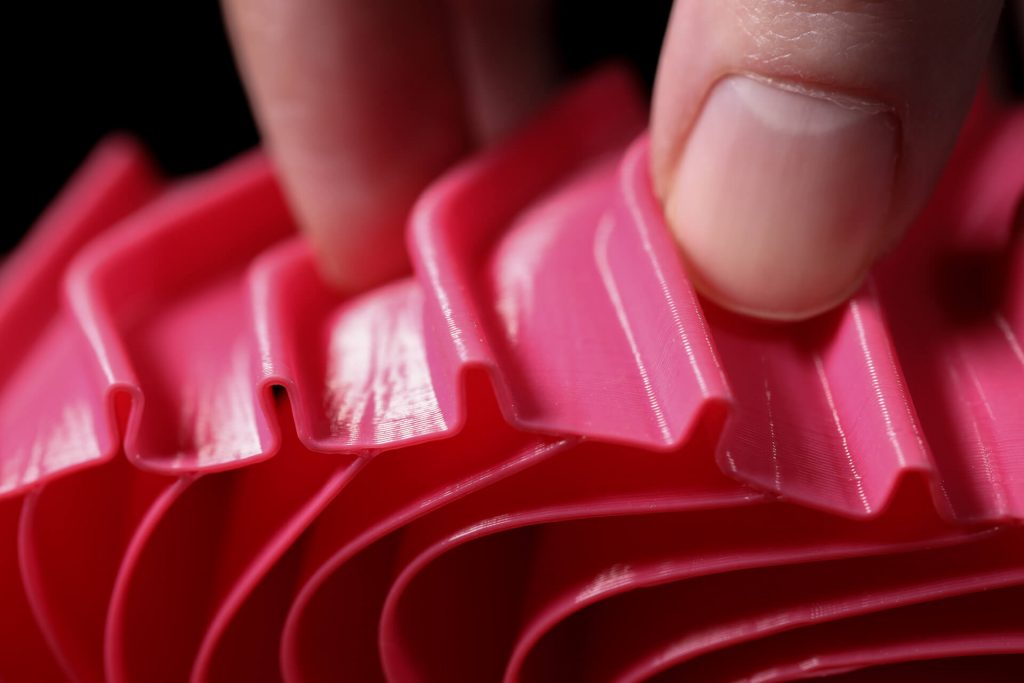

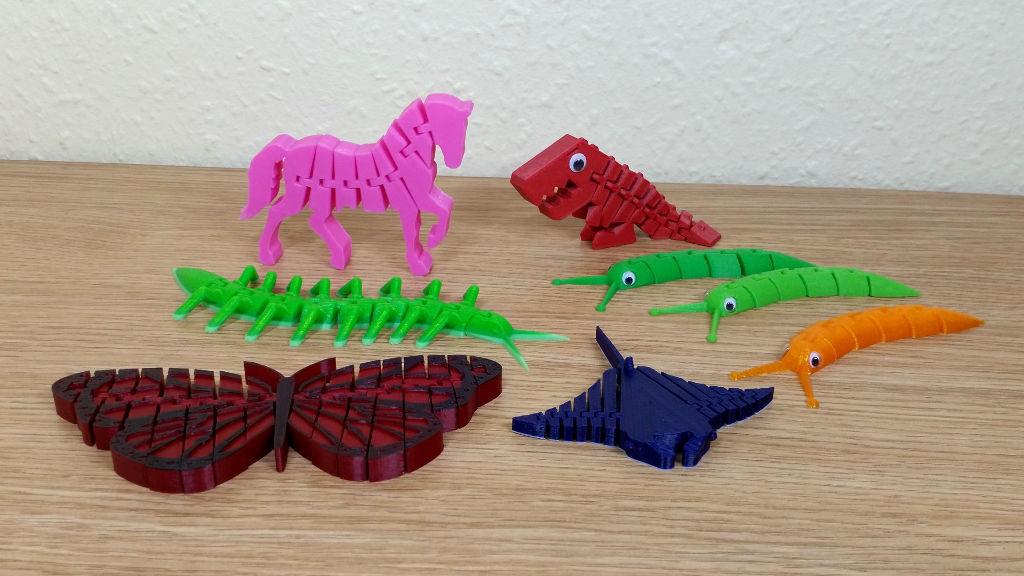

Glue is the default go to for joining 3d printed parts be that super glue gorilla glue or two part epoxy but while that is a common and flexible choice its not the only one and can be pricey in comparison to some other options. There are several types of tpe with thermoplastic polyurethane tpu being the most commonly used among 3d printing filaments. Traditionally one of the biggest difficulties with printing fabric has been the comfort and flexibility of the products so they set out to fix this. A range of hardnesses durometers are available which work well for components with elastomeric features like gaskets seals and housings.

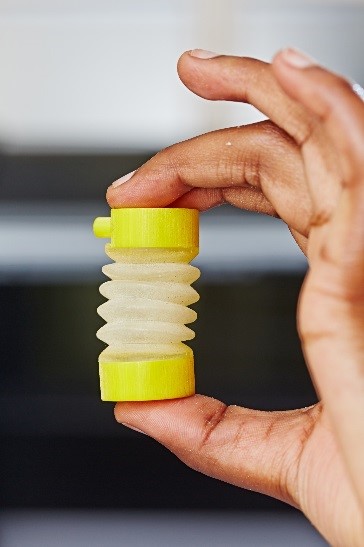

Materials like matterhackers pro series flex ninjatek or soft pla all behave similarly to rubber which makes it perfect for printing things like gaskets stoppers or even phone cases. Thick layers in order to achieve industry leading accuracy and precision. Create the spare part yourself. Flexible filaments are made of thermoplastic elastomers tpe which are a blend of hard plastic and rubber.

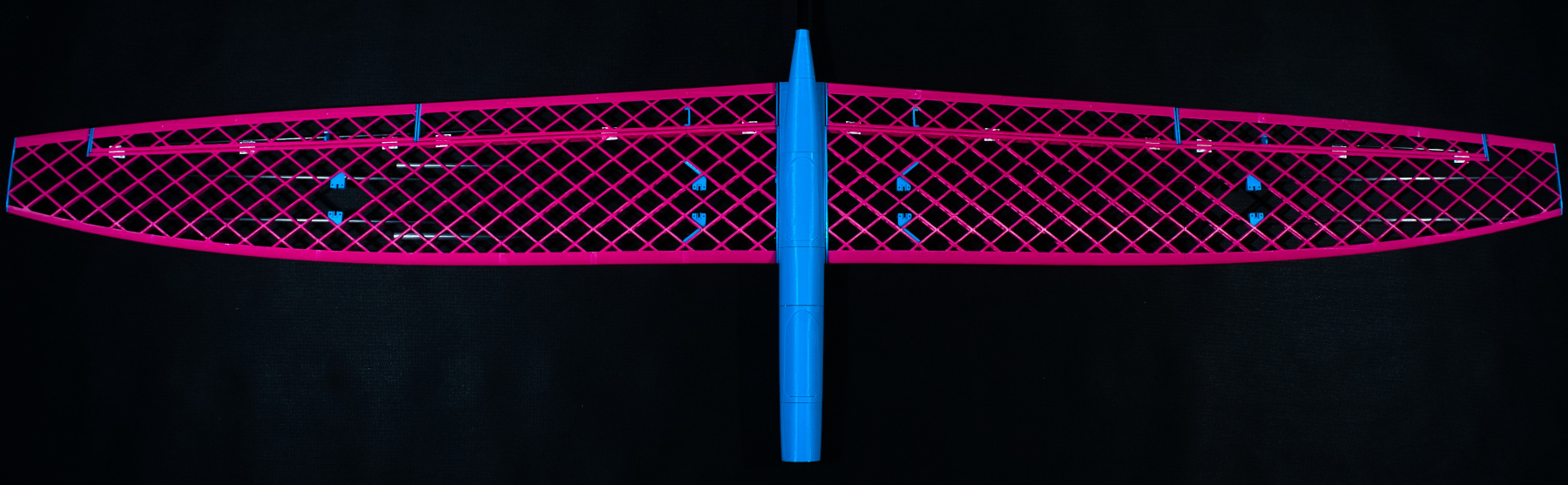

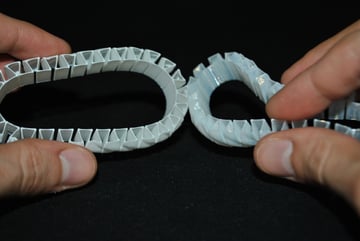

Protect your gopro hero 567 more than ever before with these sigan flexible 3d printed casenot only will these cases save your camera crash after crash but also it will great do it with the vibrant colors optionsfeatures very durable case to mount and protect your gopro hero5678 printed from flexible and forgiving tpucolor. Mit one of the most recent developments in the field of 3d printed fabrics comes from a group of researchers at mit. Flexible filaments are all thermoplastic elastomers that can provide the perfect amount of bend elasticity and strength to your 3d printed parts. As the name suggests this material is elastic in nature allowing the plastic to be stretched and flexed easily.

Tpu on the other hand can be thought of as the newer version of tpe. Microfine tm is an exclusive material developed at protolabs that can build parts with a minimum feature size of 00025 inyes thats not a typo. However its softness makes tpe a very challenging material for machine extruders to 3d print. Our industrial 3d printing service ensures accuracy and repeatability so you get highly precise partsevery time.

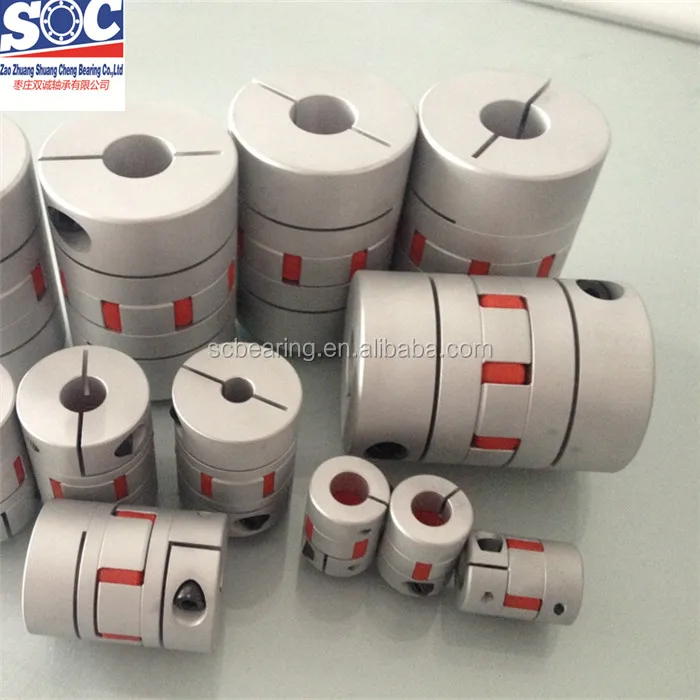

An alternative way to use 3d printing to create elastic parts would be to fabricate a mold out of ordinary pla or similar in which to cast silicone or rubber parts. In terms of its mechanical properties the material is fairly durable rigid and.

/cdn.vox-cdn.com/assets/3726557/kinematics_nervous_system_01-640x414.jpg)