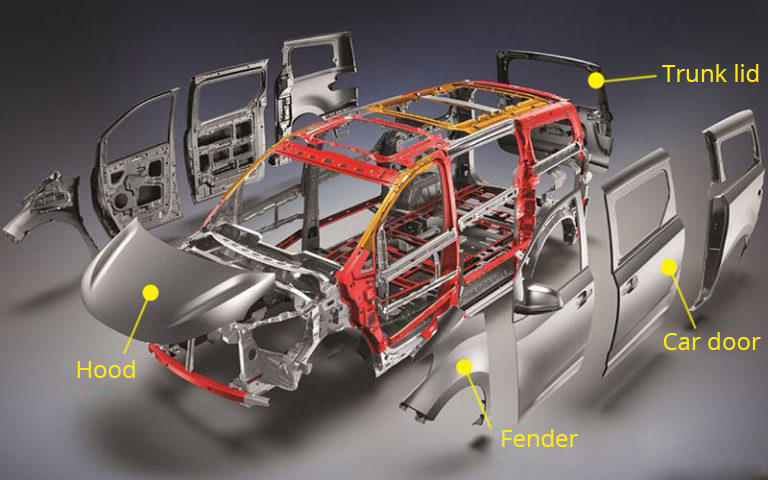

3d Scanning Car Body

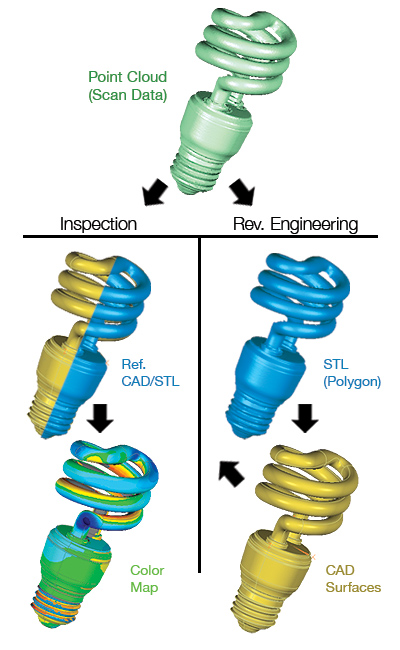

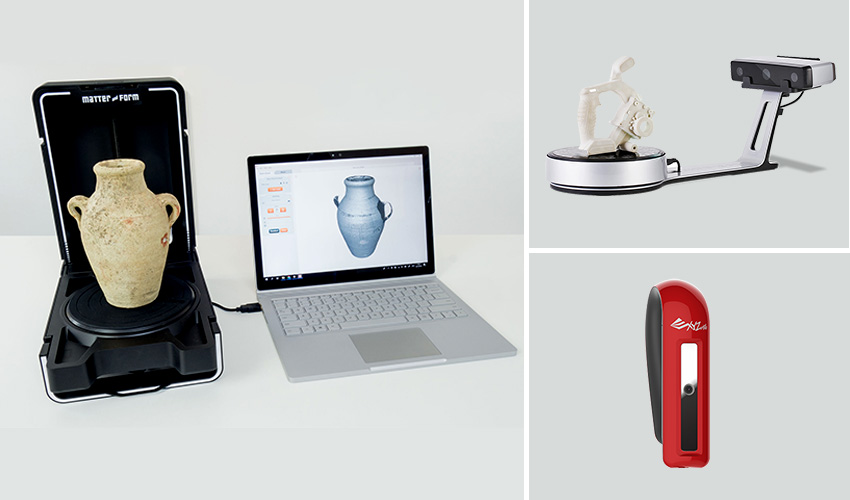

A typical handyscan 3d workflow.

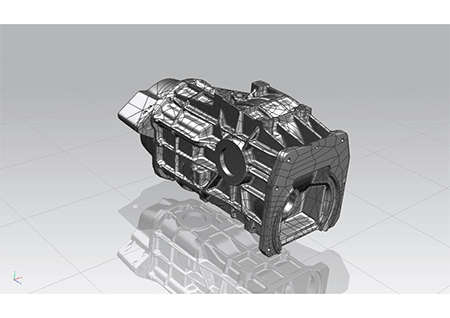

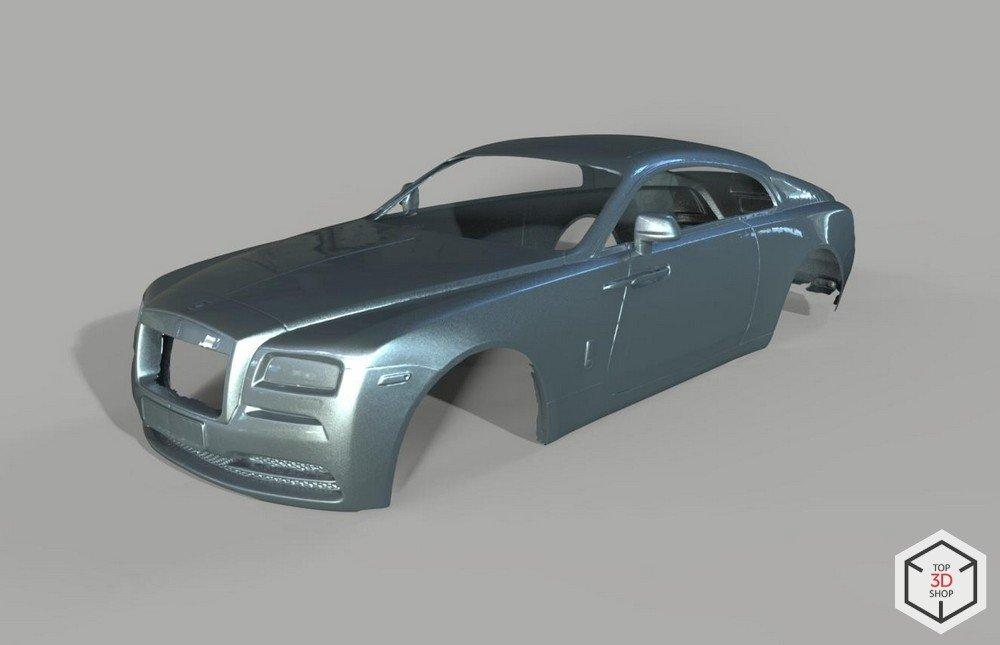

3d scanning car body. A rexcan 420 from the solutionix range of rexcan structured light 3d scanners was used to capture the shape of the gearbox casing. Additionally positioning targets are placed throughout the body of the car spaced about 4 to 5 inches apart. Sitting behind the wheel of a mercedes e350 you could technically drive at a speed of 150 mph. Over the past 20 plus years we have scanned more than 500 vehicles refining our process equipment and techniques to be able to provide our customers with the highest quality models available.

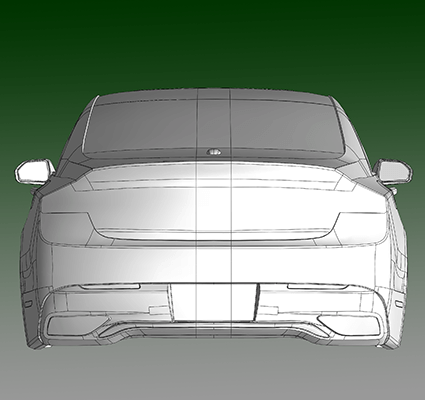

These reflective sticker targets will help form the reference model for the scan. Before the actual scan can occur the car is prepped by spraying a very thin white coating on the reflective or transparent surfaces namely the windows and lights. Thanks to artec leo this sprayed down body of a mercedes e350 was scanned in just 20 minutes and ready as a 3d model only an hour and a half later. Designed for larger objects leos job started with the hood of the car followed by the individually scanned sides.

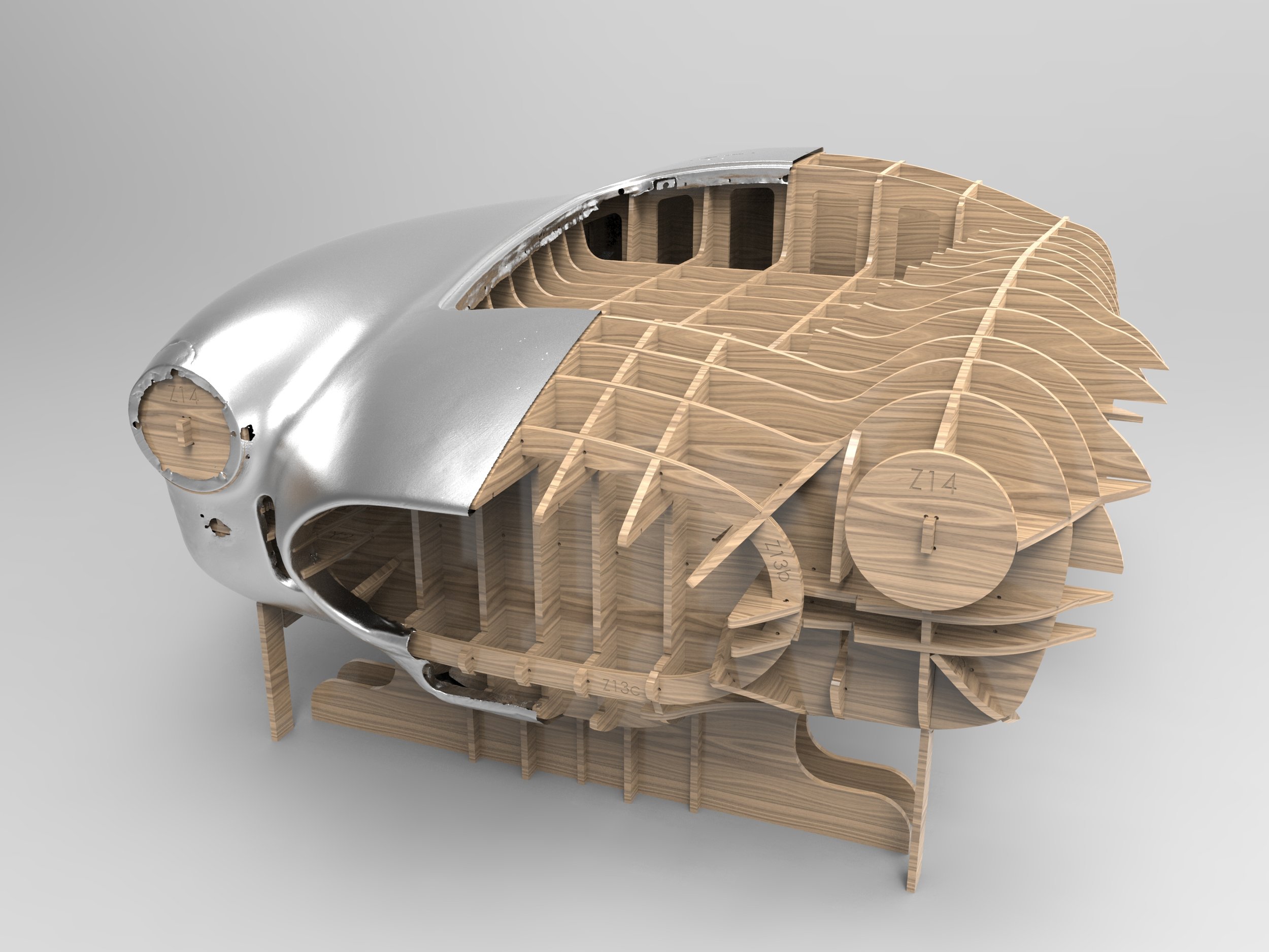

Calibrated in detroit in many ways envisiontec was born out of the us. The 3d scanning process is where speed comes into brian coombs life yet again. 3d scanning reverse design of automobile automobiles have become a means of transportation with various types and specifications and are widely used in various fields of social and economic life. 3d car scanning automotive 3d car scanning has driven mimic 3d to become the industry leader in 3d scanning services.