Advantages And Disadvantages Of 3d Printing Compared To Injection Molding

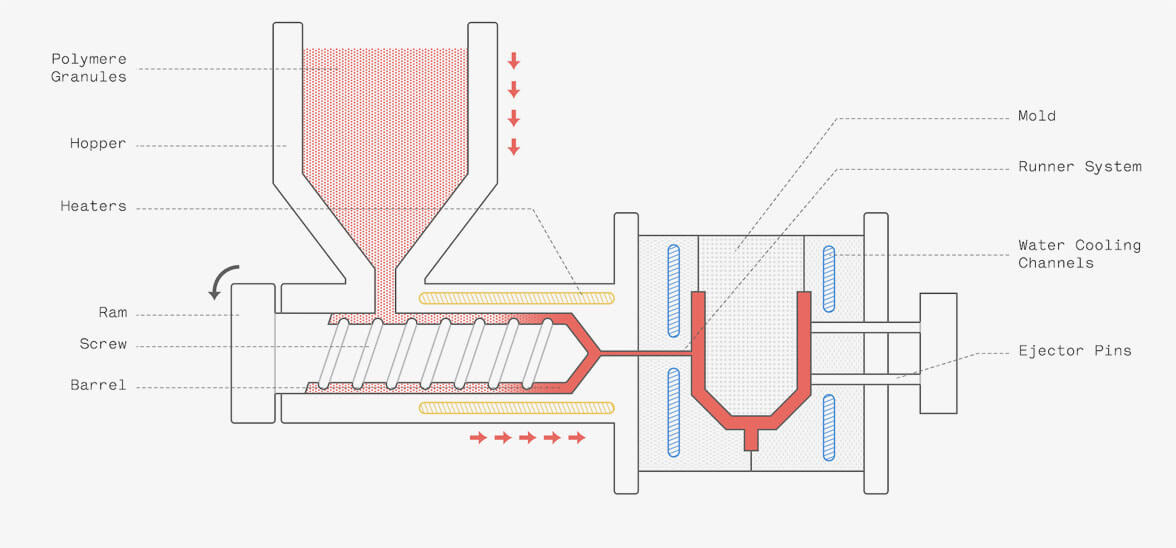

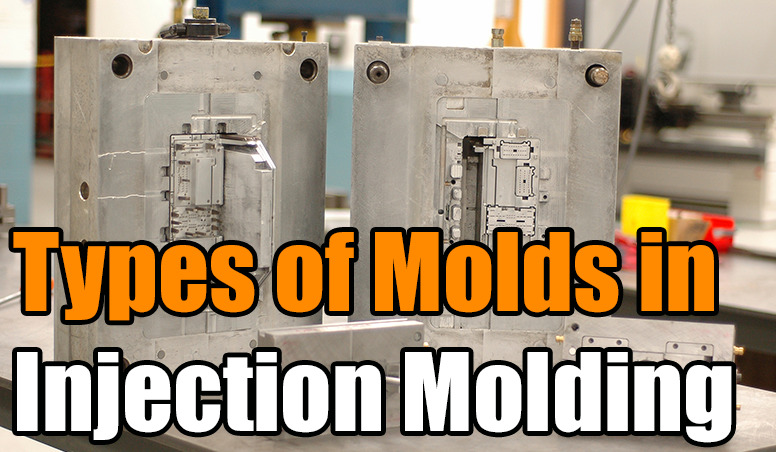

Plastic injection molding is such a precise method that it can manufacture almost any type of plastic part.

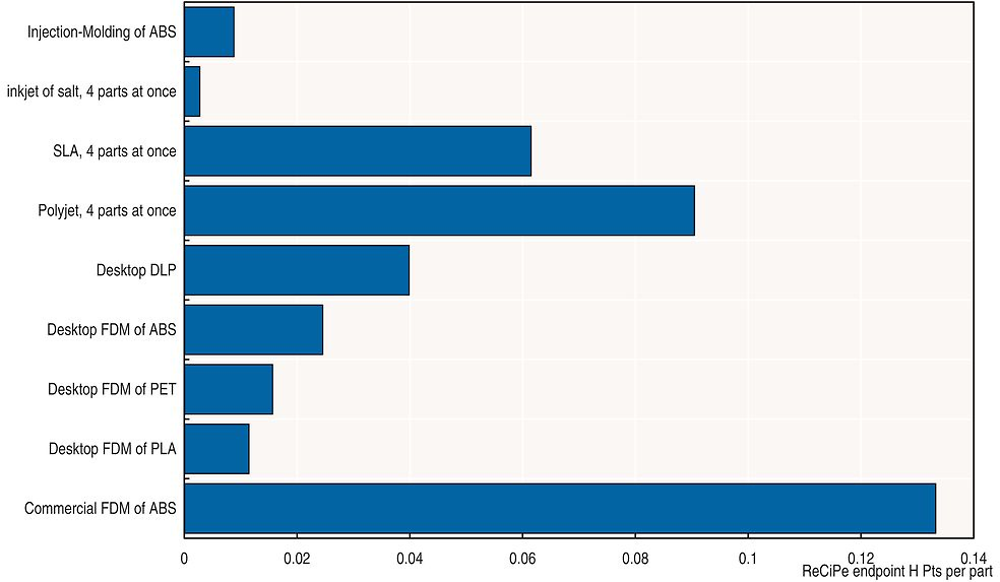

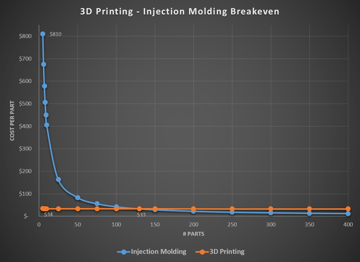

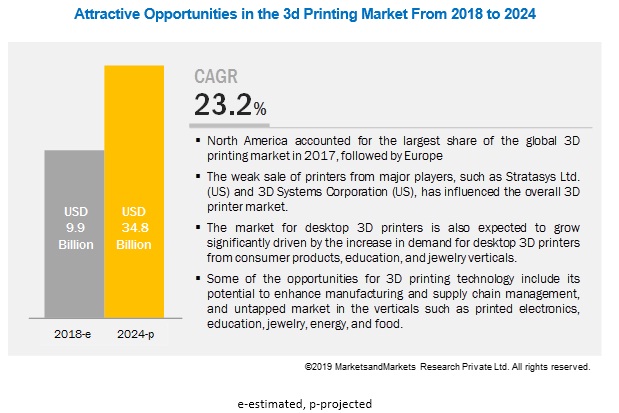

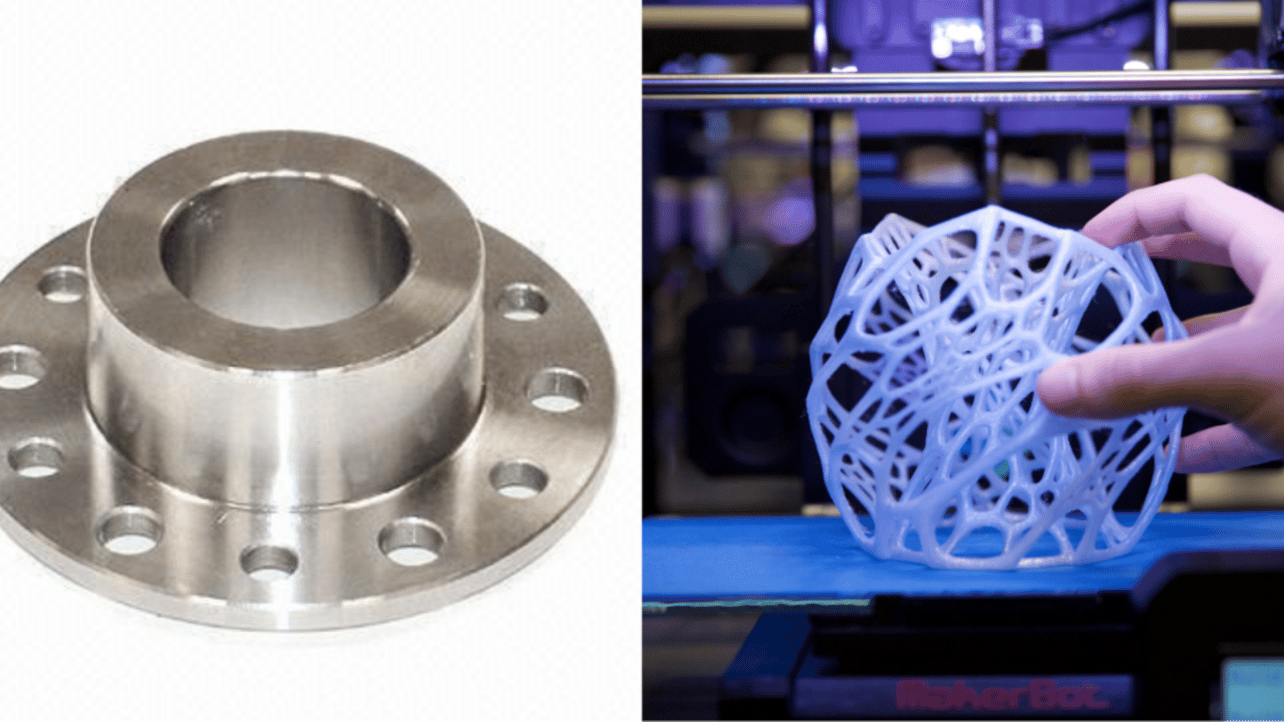

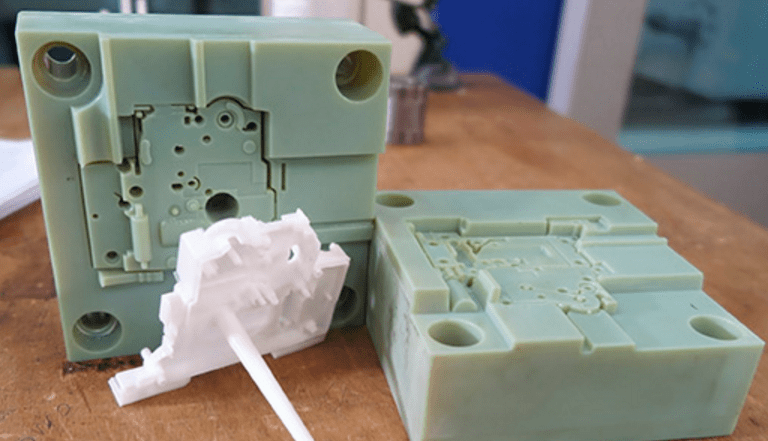

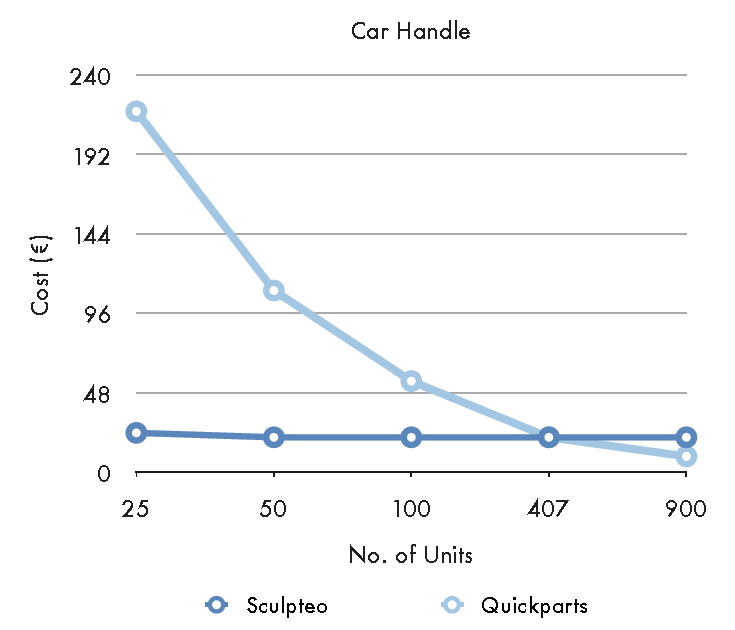

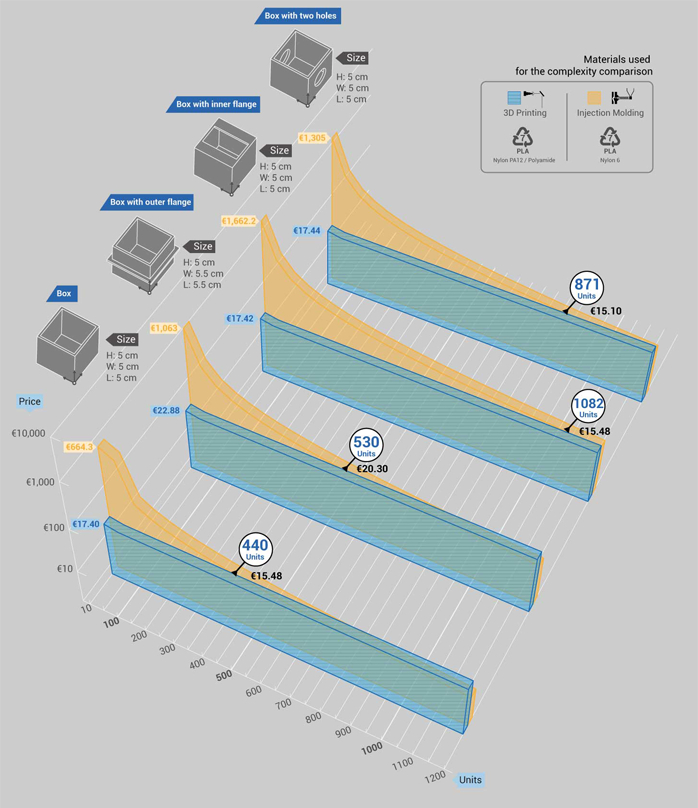

Advantages and disadvantages of 3d printing compared to injection molding. With injection molding the initial cost is extremely high and at an average of 1000 parts you will have a break even point competitive to 3d printing. As a customer of an injection molding supplier you must pay for the injection molding cost amounting to the high thousands or tens of thousands of dollars. A 3d printed mold will not be as durable as for example a tool steel mold but can serve as an effective solution for mid volume production runs that might not for any number of reasons clearly call for either 3d printing or injection molding with a tool steel mold. Like injection molding 3d printing also has its downsides.

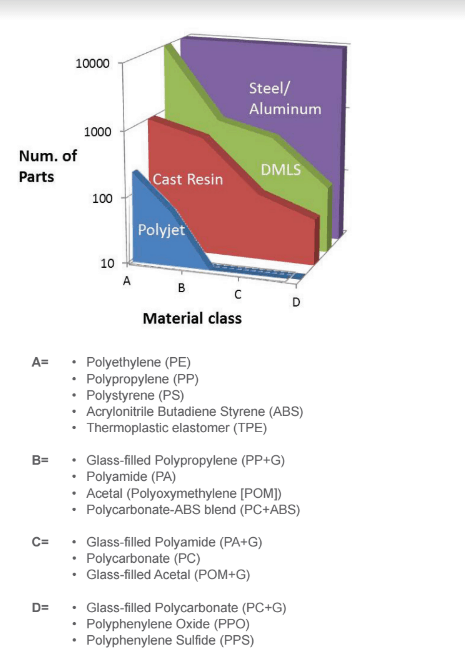

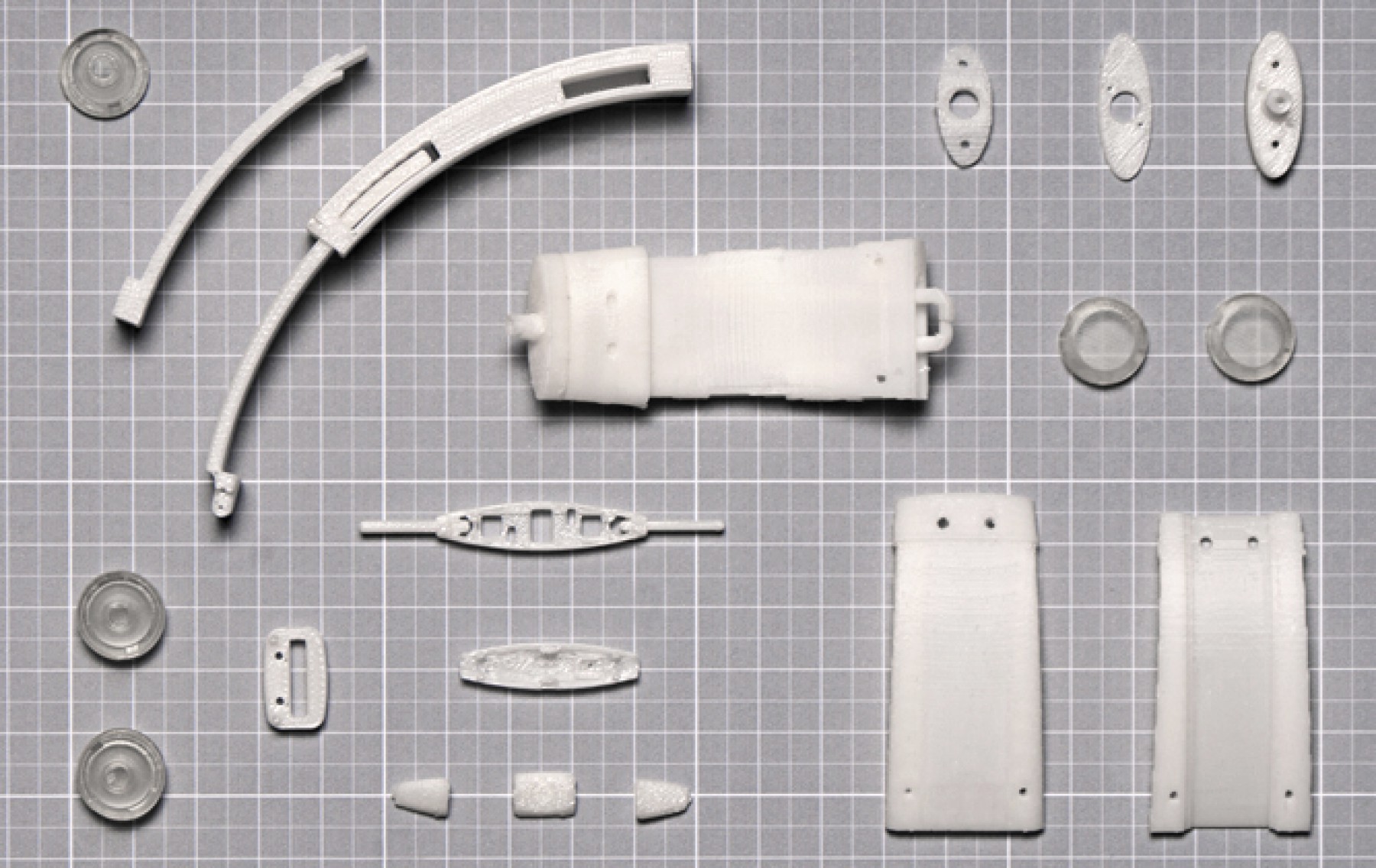

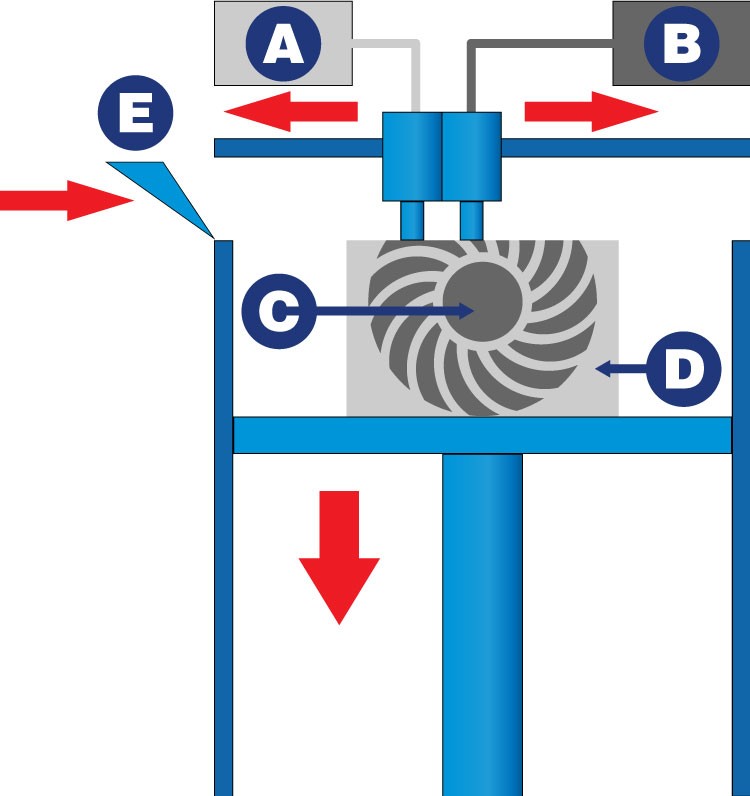

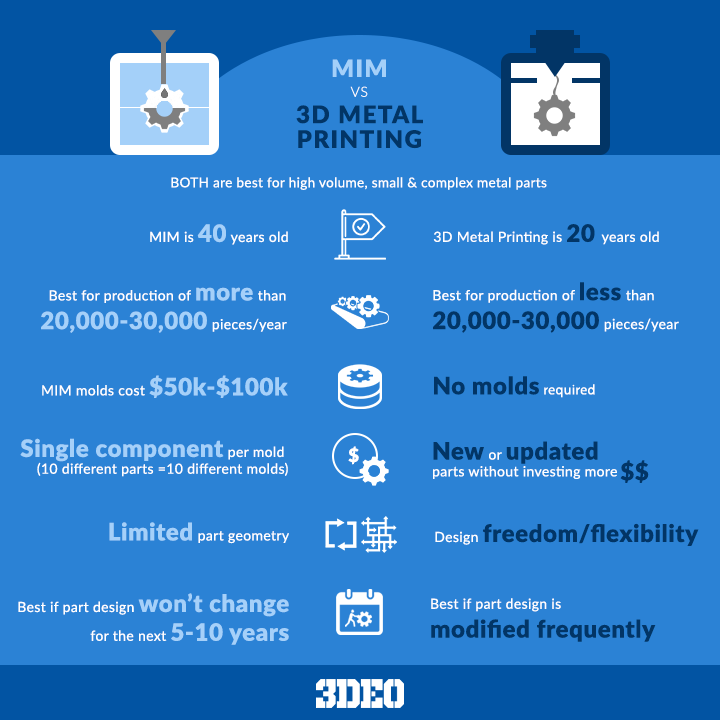

Compared to other forms of small scale production 3d printing also offers the advantage that you can make nearly any geometry you need. Unlike injection molding or reductive manufacturing where only certain shapes and certain sizes of these respective shapes can be made 3d printing can make just about anything you throw at it. Instead of squirting liquid plastic into free form layers injection molding involves forcing liquid plastic into a metal mold which has been precisely machined into the final outside. Unlike injection molding where liquid plastic is injected into a mold 3d printing heats the material up just enough so that each layer bonds together.

Although injection molding has its limits for the size of each individual piece that can be created this process can produce a much bigger piece than 3d printing. Today many 3d printing processes are expensive slow and may produce parts that are not up to industry quality or material standards. There are certain design constraints but the molds allow the finished product to be very precise. For 3d printed molds.

Because of the industrial scale of its tools injection molding works on a bigger scale which is a big advantage even if you still have to print separate parts to put together later. Meanwhile 3d printing machines typically only cost a few thousand dollars without the upfront setup cost. Here at universal plastic mold we specialize in plastic injection molding which has its own set of advantages and disadvantages when compared with 3d printing. So what process should you use to manufacture your parts 3d printing or injection molding.

Easy to make changes. If youre looking to order and produce in smaller volume runs 3d printing will be the most cost effective and efficient solution with its low upfront overhead. 3d printing does require the right type of printer that supports the type of materials you want to create your parts and components from.

.jpg)