Diy 3d Printer Plans Pdf

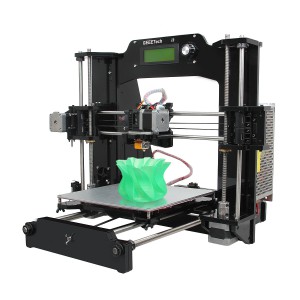

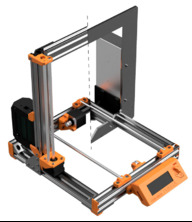

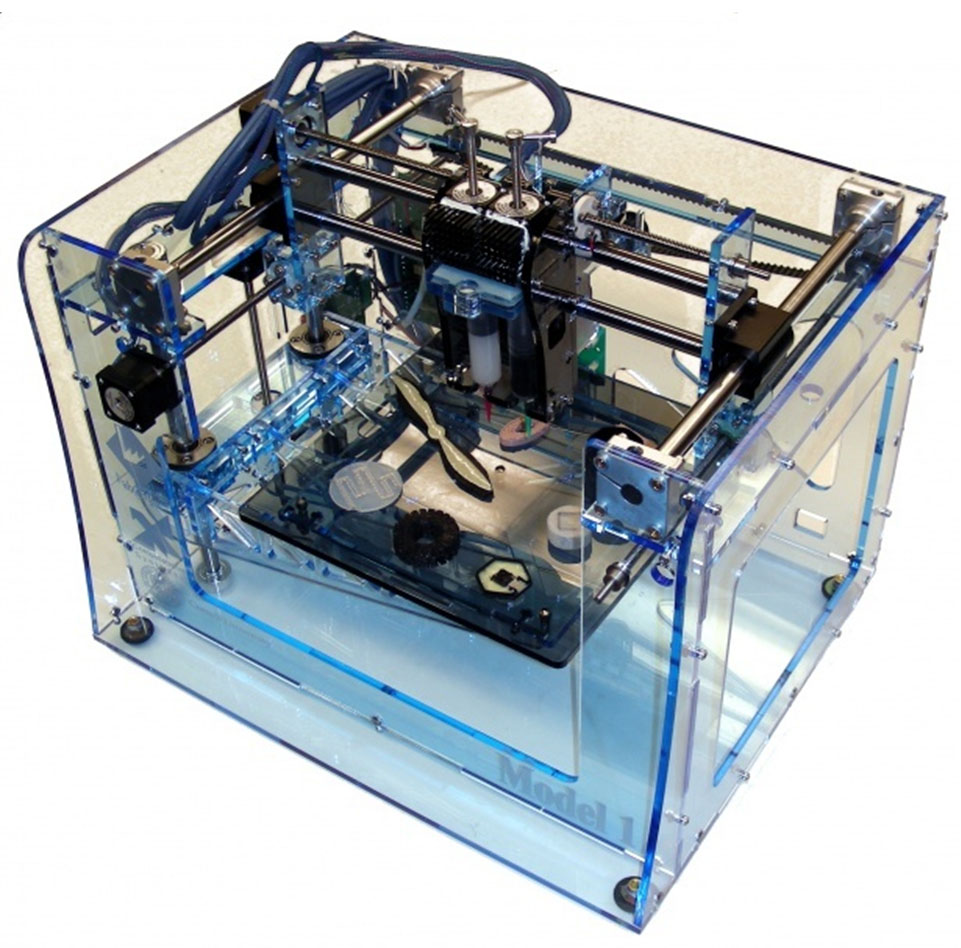

Scratch built 3d printer this 3d printer diy kit is for those who prefer to build thing from scratch or in other words go to diy reprap route.

Diy 3d printer plans pdf. The coolest part is you can use your printer to build an copy entirely by itself. Click on the links in the pdf version. They have been around with some minor changes since then. In theory it can save you some money and since you build it from scratch you will know every nut and bolt in it by the.

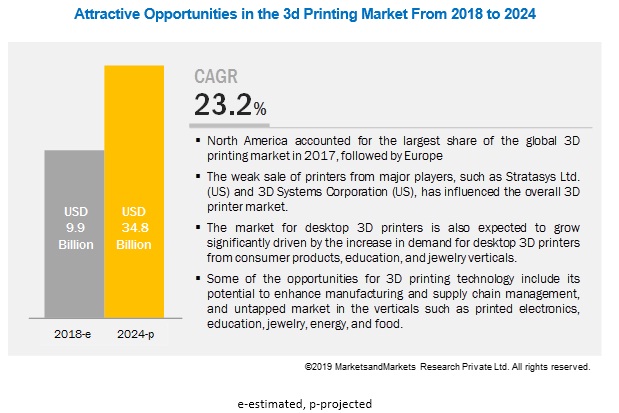

I have always been amazed by the idea that i can design and print my own parts. There is a huge community you can get tips from too. 2 upcoming events tchotchkes. These are mostly printers based on the reprap 3d printer and you can choose to either make one on your own or buy a kit and assemble the parts.

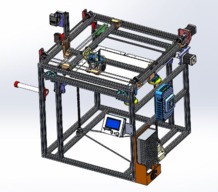

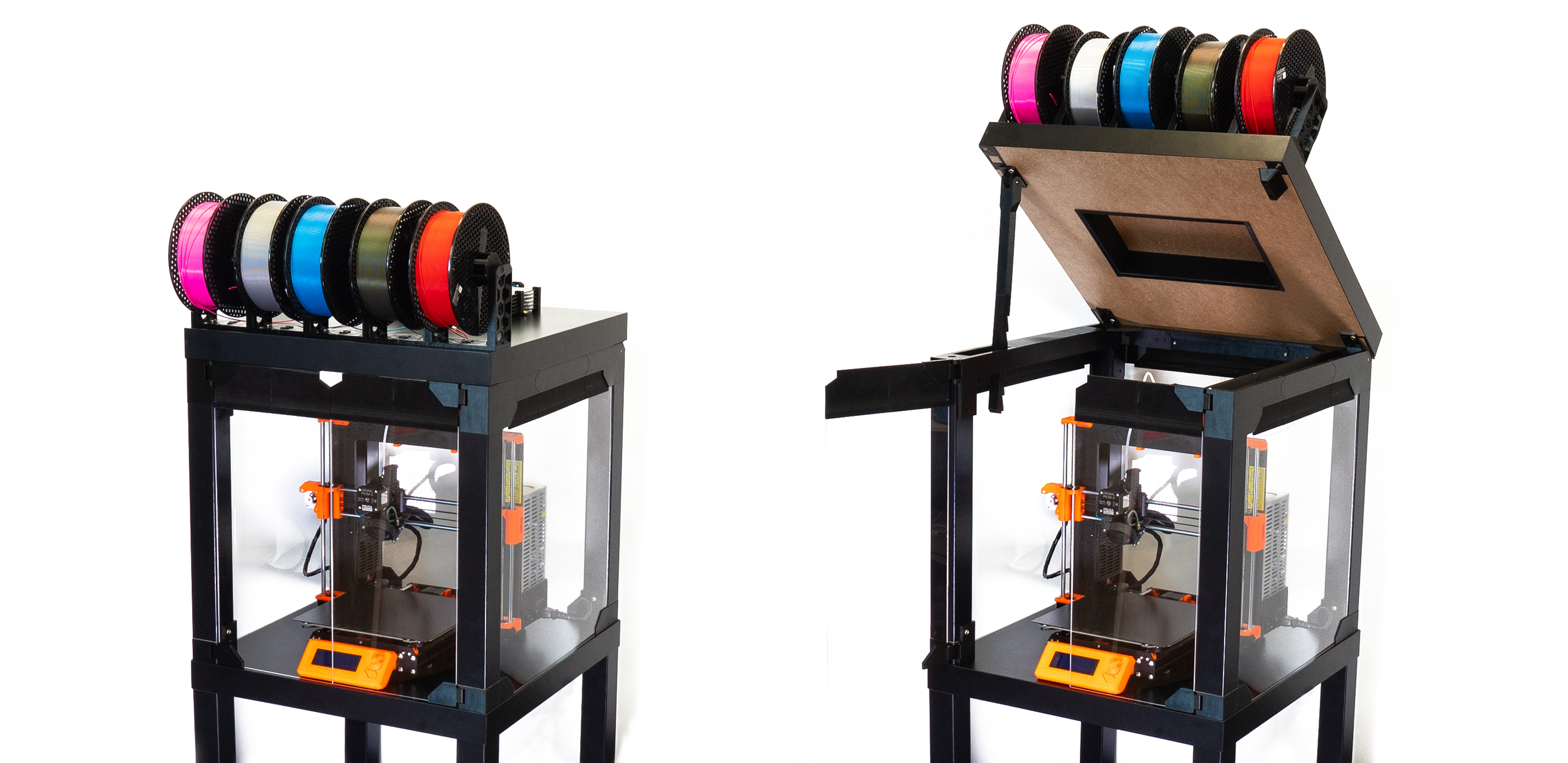

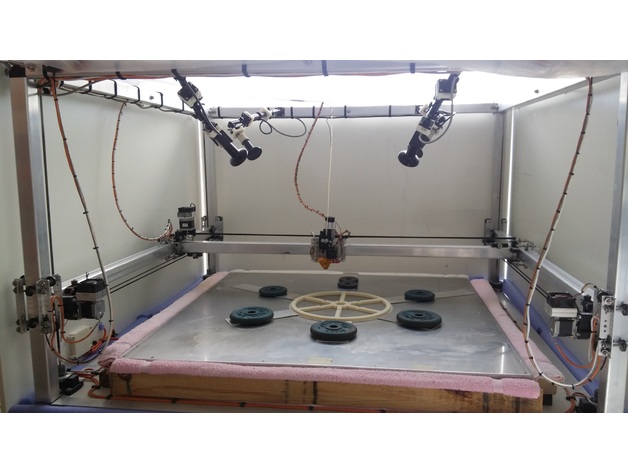

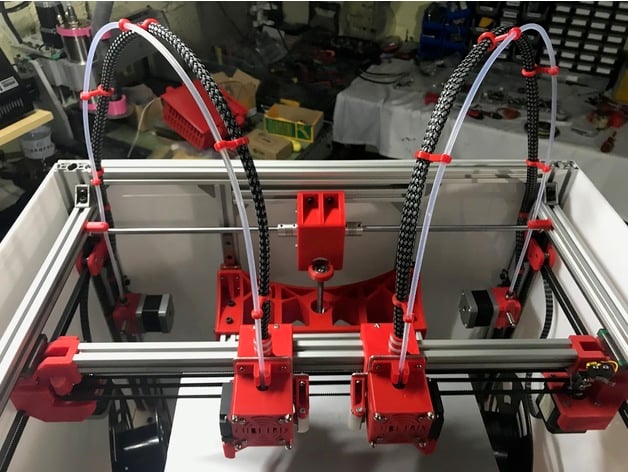

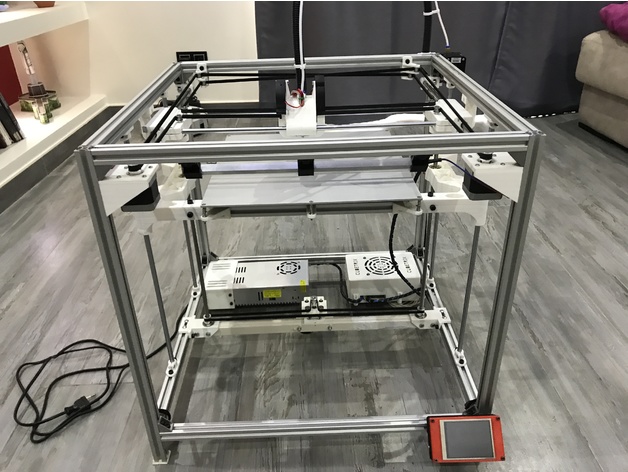

An 8020 build with 1010 extrusion 1 square tubing rough size is 24x24x36 600x600x900 the expected usable print area 215x215x32roughly 510x510x760 an xy 3d printer with 3 extruders and 3 z axis 09 degree motors the table z axis will lift up to the xy carriage on 3 12mm linear rod and 3 8mm lead screws corexy designs complete and z axis build is started dont have a 3d cad system. Openscad cad cam process. He is currently a contributor to boing boing wink books and wink fun. And he has a new best of writing collection and lazy mans memoir called borg like me.

Open source diy 3d printer. Open source 3d printer. 3d printer hardware overview 3d printer action movie solid modeling. Its 3d meaning its not flat like a piece of paper.

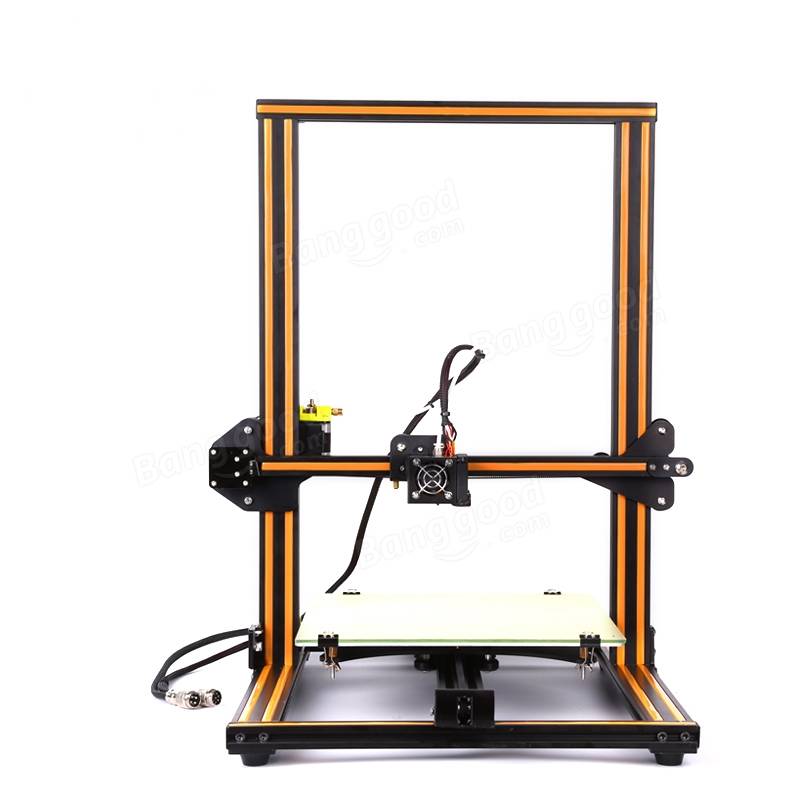

There are a lot of 3d printer kits to choose. Repraps can be purchased on amazon for a few hundred dollars. Simple with less materials. You can buy parts and build your own printer.

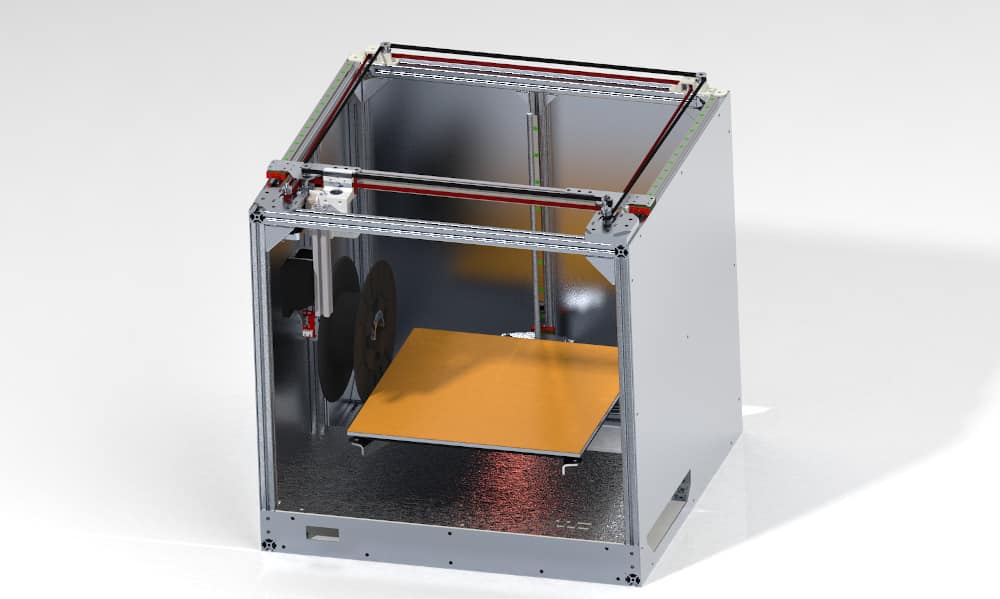

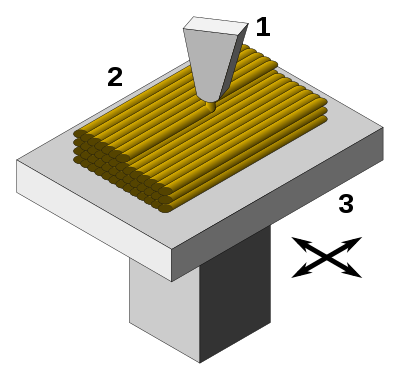

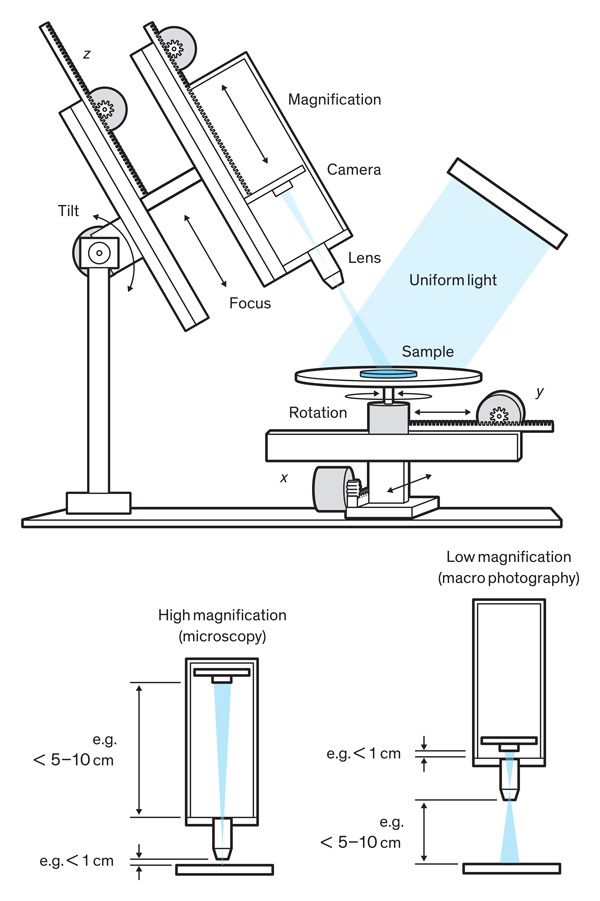

3d printing is exactly what it sounds likeprinting something that can be picked up held in your hands and played with. It must be printed by a special device called a 3d printer. The diy 3d printer plans were designed by johann c. Backlash occurs when one of the movement axes has slack caused by loose belts for example.

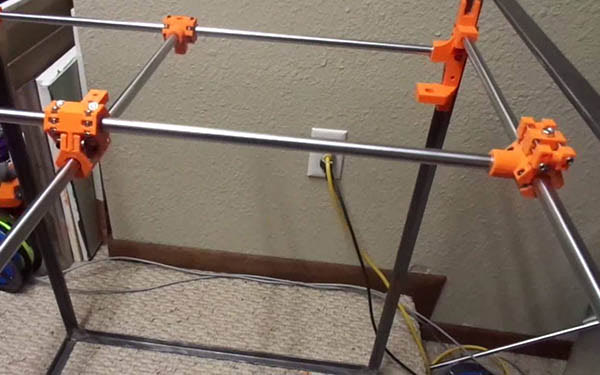

Its printing because the 3d object doesnt just magically appear. He is the author or editor of over a dozen books on technology diy and geek culture. The concept of the delta design eliminates backlash problems. Apart from some essential advantages this approach has also its disadvantages.

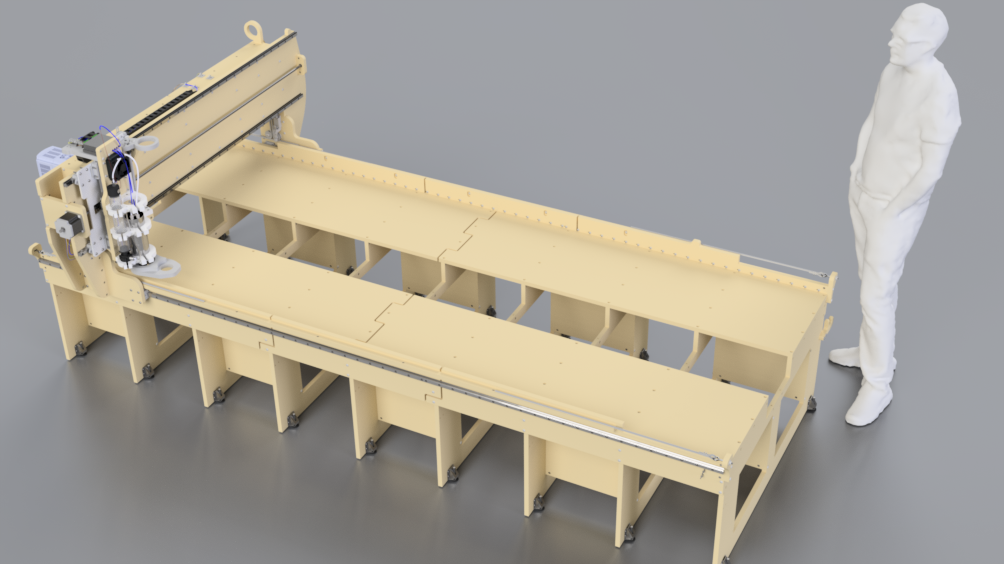

Gareth branwyn is a freelance writer and the former editorial director of maker media. There are many diy projects today that can be used to make 3d printers at home and some of them can be found here. Over the past years 3d printing has opened out amazing opportunities to every builder and maker out there to become herhis own independent producer and designer. Frame is made of a single 4 long 2 12 square tube 16 gauge15mm0598 thick cost.

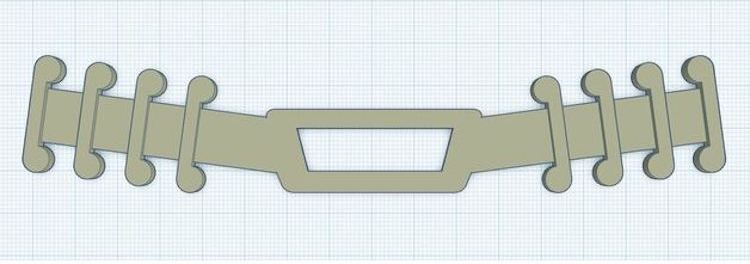

Kossel on reprap wiki. With this design there is less plastic parts stronger structure all wire.