Homemade 3d Printer Filament Extruder

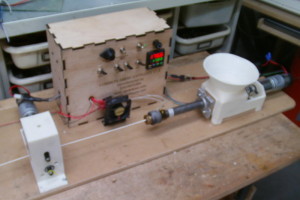

The machine depicted in photo 1 is the noztek pro a sleek desktop type extruder from the united kingdom.

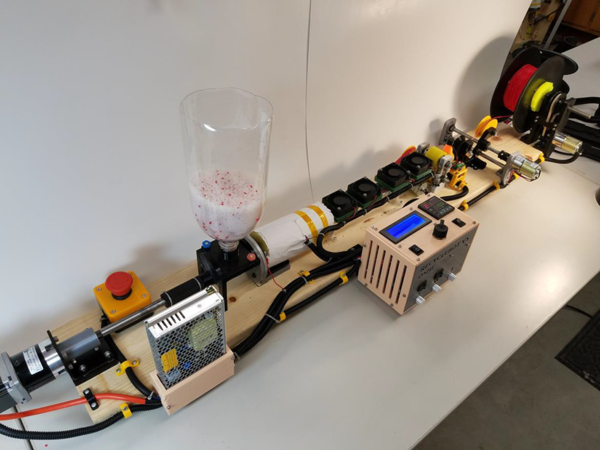

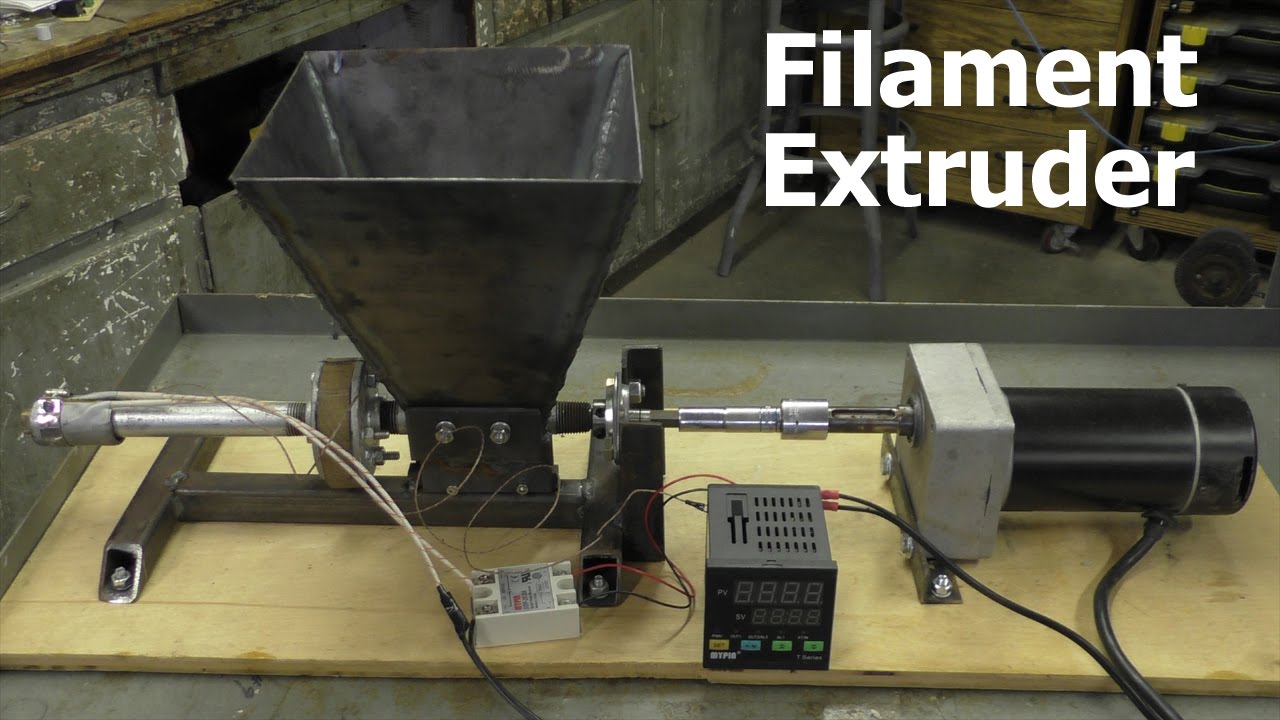

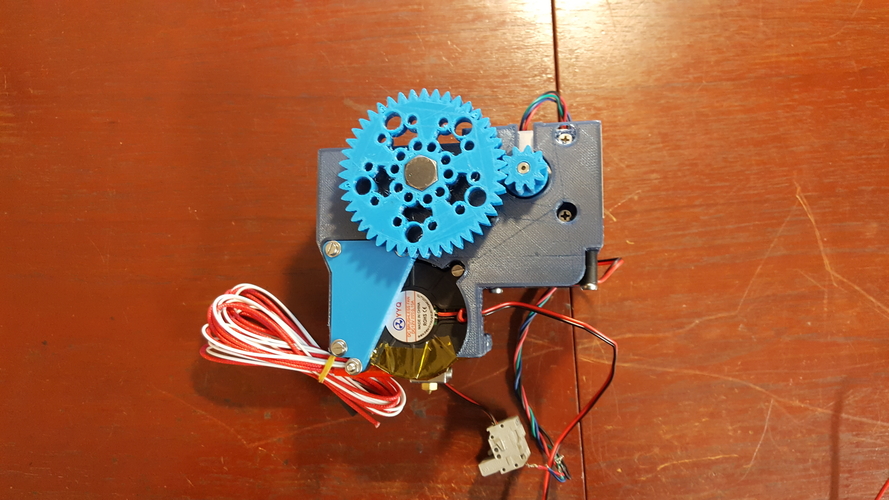

Homemade 3d printer filament extruder. This can be due to many different reasons such as your nozzle is too close to the print bed your stepper motor is losing steps your extruder gears arent gripping the filament tightly enough or you have issues with your bearings which. The photo below shows you how such an extruder looks like. 3d printing 13 things i wish i knew when i got started duration. Recycle plastic into filament creating a closed loop recycling system.

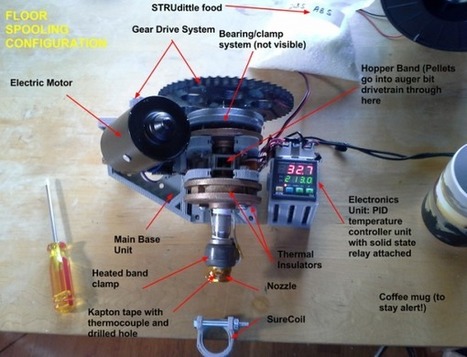

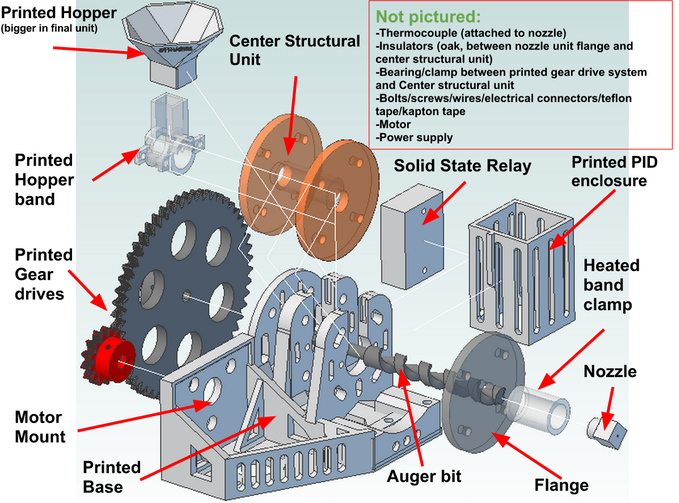

In fact they developed a so called filament extruder for home use ie. 3d filament extruders make filament from almost any plastic. Everything can be found at your. Except for the electronics everything listed here can be bought at your local hardware store.

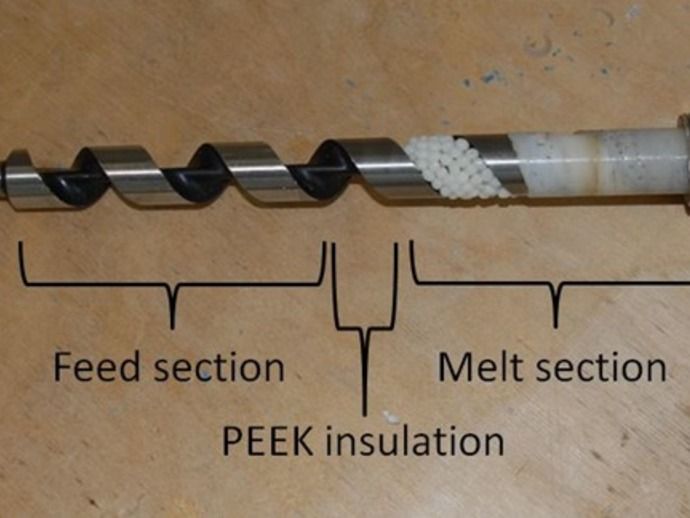

The stepper motor turns a screw shaped barrel which forces the melted plastic out to the extruder nozzle creating the new filament. Various lengths and types of wood for construction of the base. My review of the felfil evo filament extruder duration. They will serve as a.

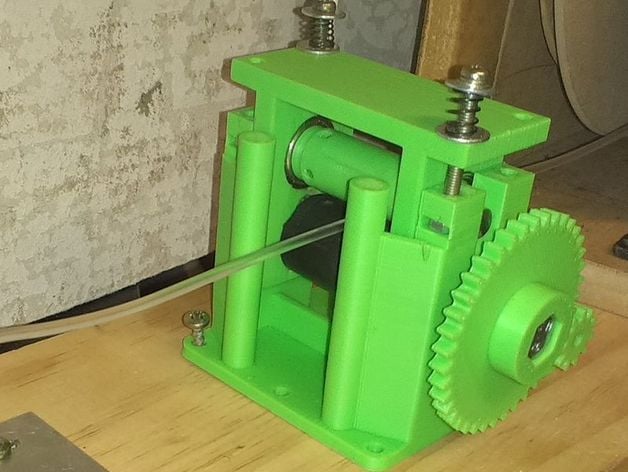

Build your own 3d printer filament factory filament extruder step 1. The tutorial was created by user cpriolo14 who built the simple device for. A machine capable of spewing out plastic filament which you can afterwards use in your 3d printer. Our filament maker system.

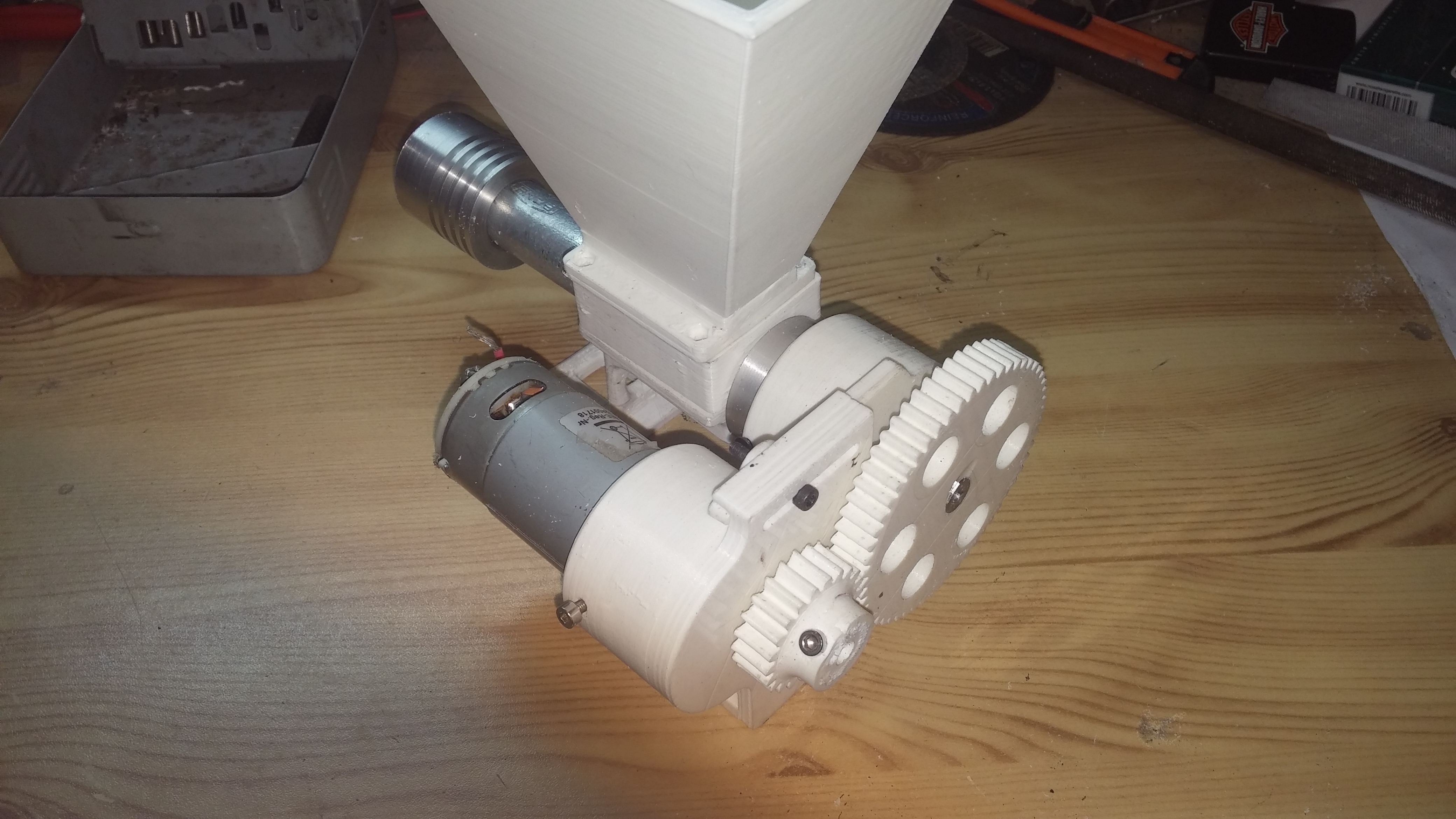

Allowing you to 3d print with the materials you use for production. Extrude filament in style source. This extruding system allows anyone to make custom 3d printing filaments at home starting from industrial pellet or chopping wrong 3d prints old models and plastic waste. 3d printing nerd 1233441 views.

Clicking noises on your 3d printer usually means that its trying to push out filament but it cant. Depending on the type of 3d printer that you have the design. Homemade diy 3d printer filament extruder step 1. 3d printing creative the felfil evo plastic filament extruder is easy to use and comes with an intuitive interface.

Its possible to set the felfil evo manually by adjusting the temperature and the motor speed before it starts to make quality filament. The felfil extrusion system is composed by felfil evo a 3d printer plastic extruder machine and felfil spooler which is a winding machine.