Markforged Metal 3d Printer Price

Image courtesy of markforged its also possible for customers to upgrade the system once theyve used the onyx for some time.

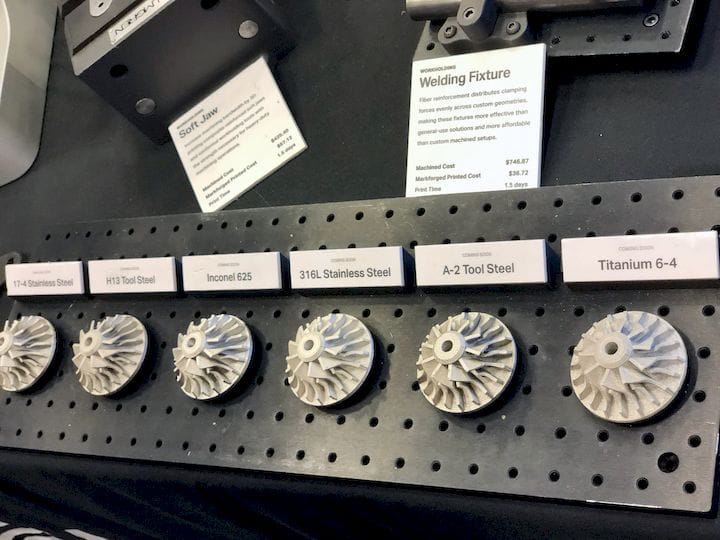

Markforged metal 3d printer price. Markforged 3d printer features. However there are plenty of printers in the mid range 3500 to 100000 which suits smaller companies with manufacturing needs. For heat tolerance print with 17 4 stainless steel. Featuring an easy to use interface automatic version control real time fleet management and cloud based collaboration markforged eiger is the worlds most advanced 3d printing software.

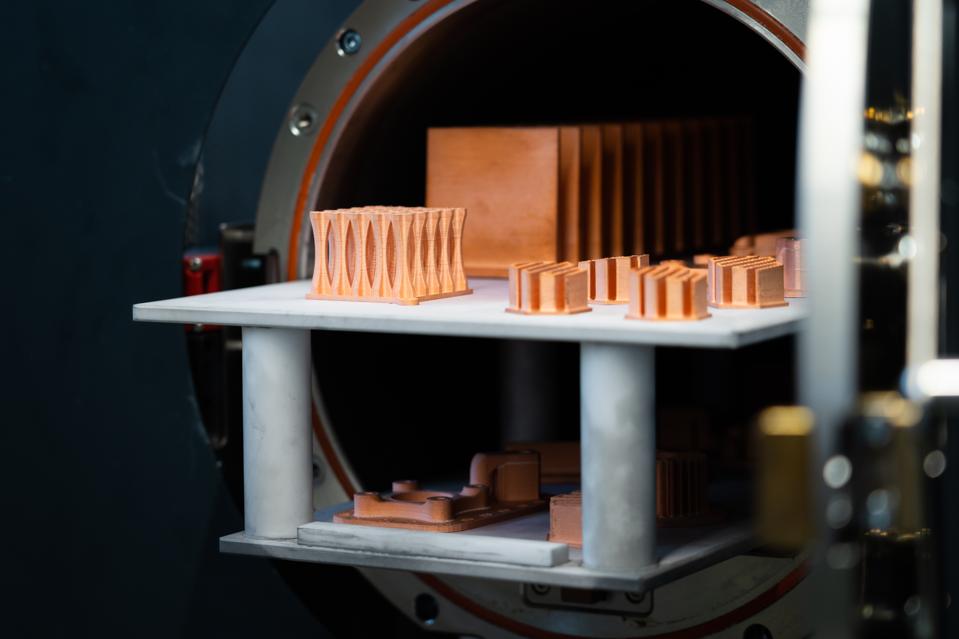

At just around 120k for a complete end to end system it is far cheaper than dmls machines which can be as much as 10 times more expensive. Printers range from 200 hobbyist printers to 1m. Eiger is available in three configurations. With markforged print carbon fiber for parts that are as strong as aluminum and dramatically lighter.

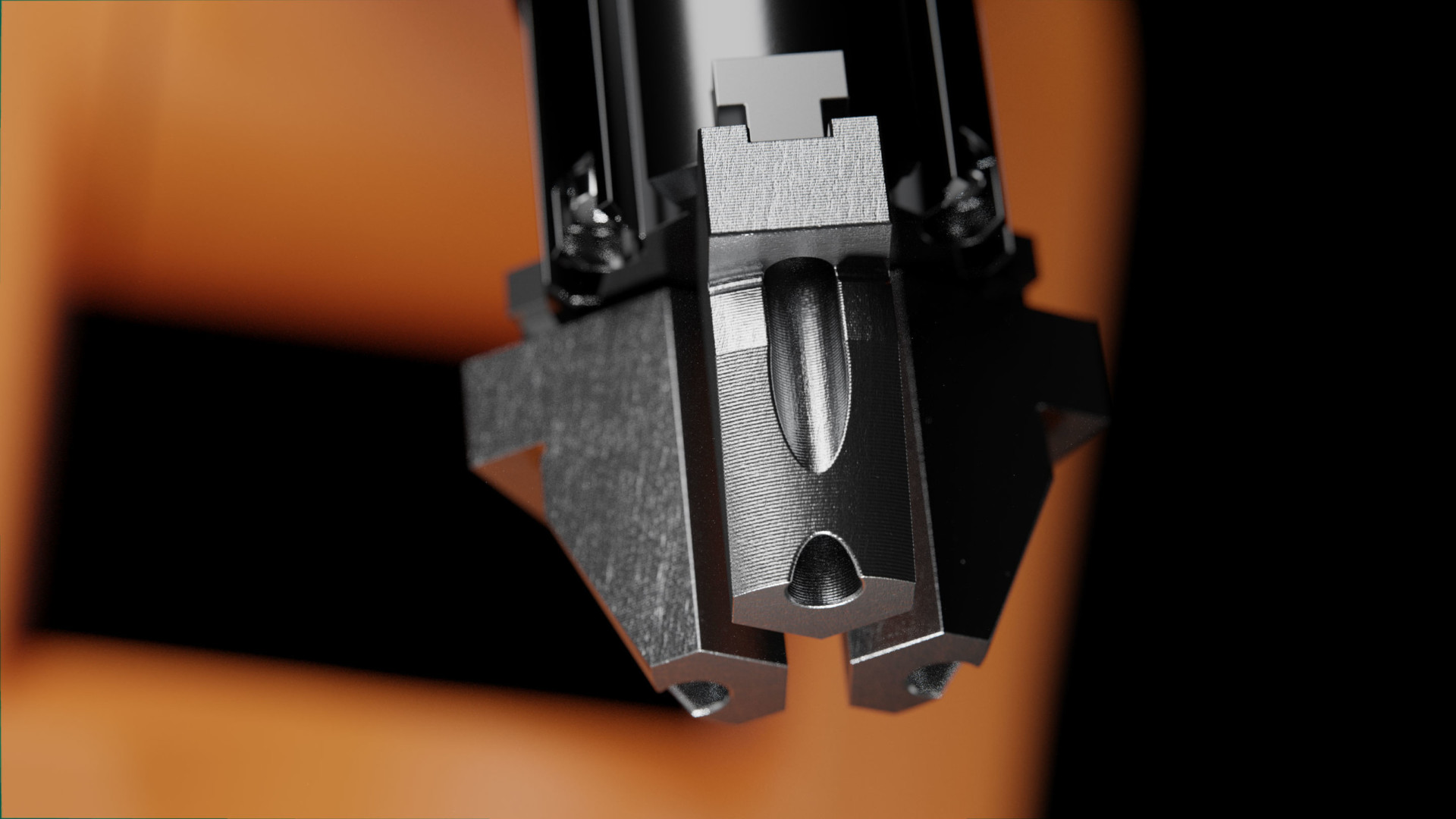

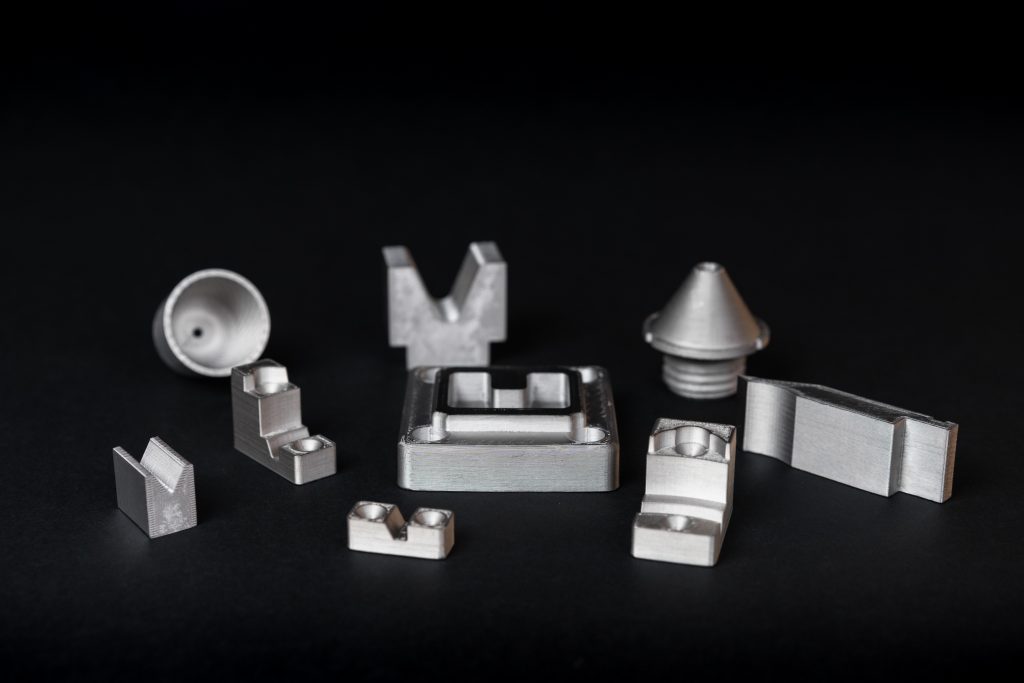

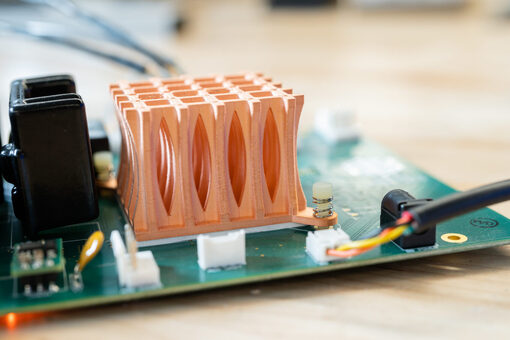

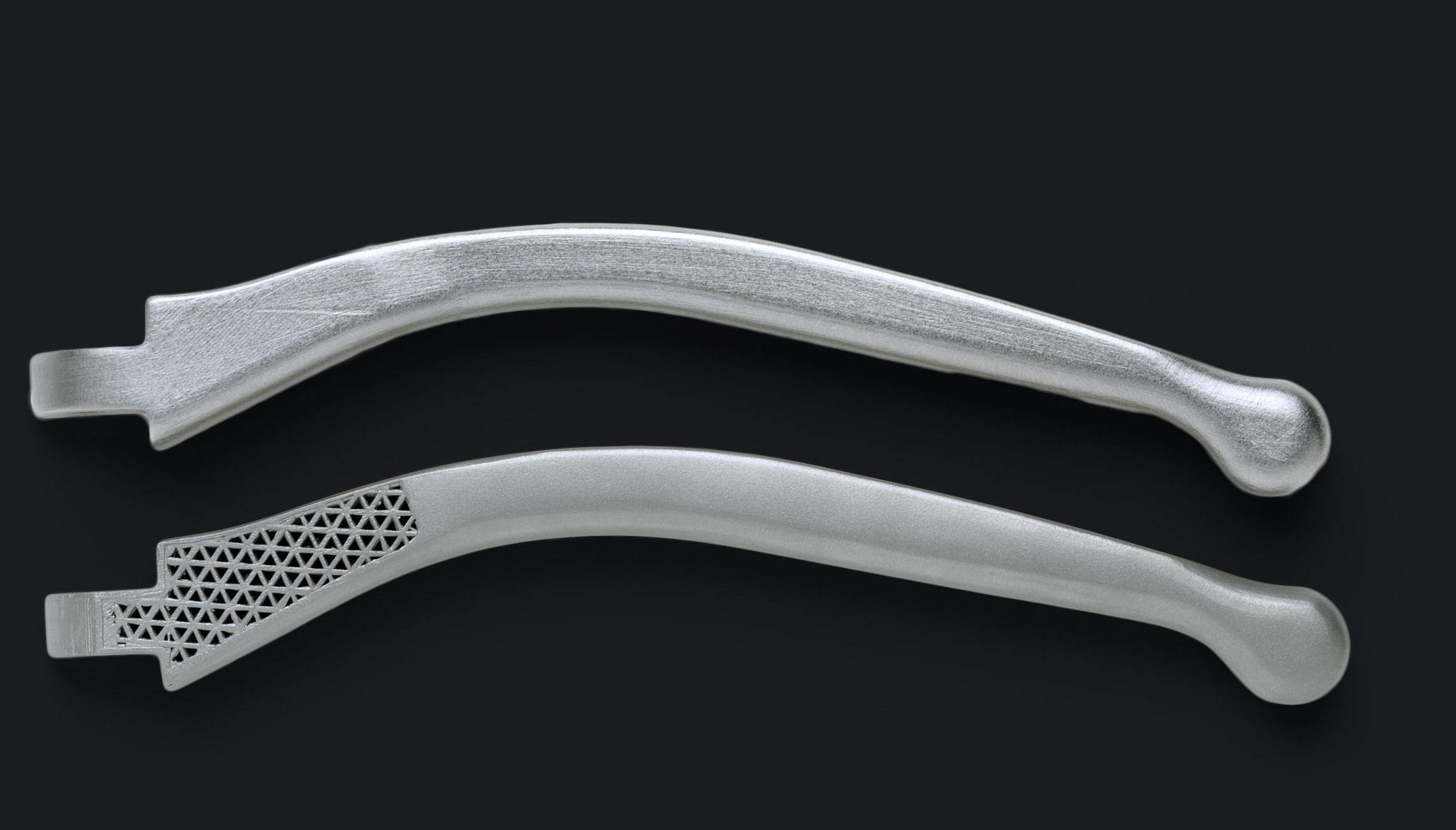

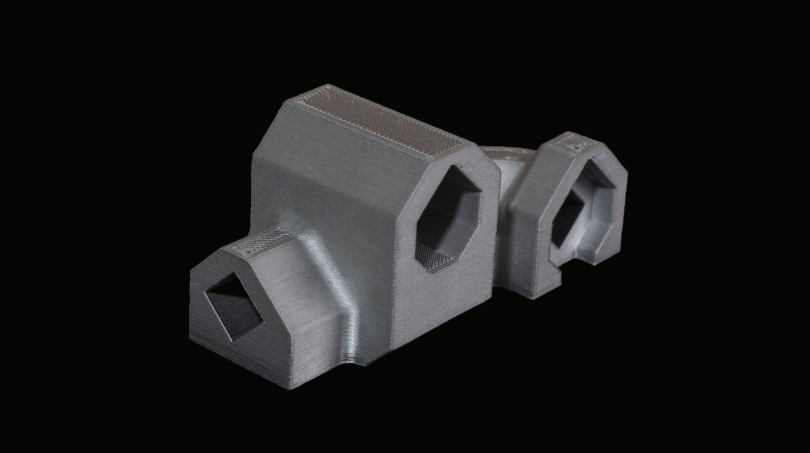

This is the markforged metal x. It can be processed and treated just like any other. By printing metal powder bound in a plastic matrix weve eliminated the safety risks associated with traditional metal 3d printing while enabling new features such as closed cell infill for reduced part weight and lower costs. 3 the part is then sintered in a furnace and the metal powder fuses into solid metal.

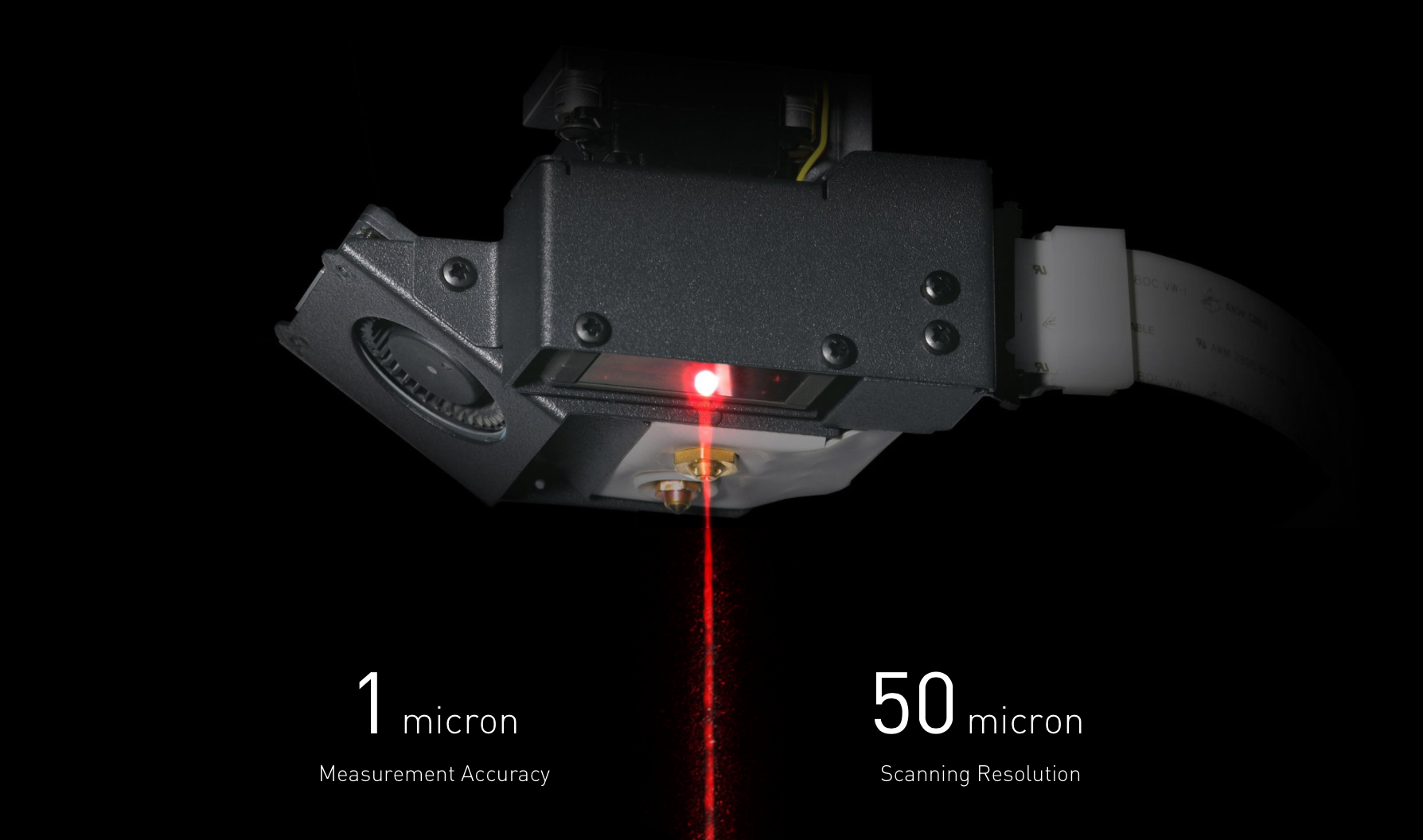

Markforged metal x 3d printing solution based on markforgeds 4th generation composite 3d printing technology the metal x is a brand new kind of 3d printer. Tesla turbine from onyx proreinforced with fiberglass. Best in class 3d printing software. Its adam technology works like this.

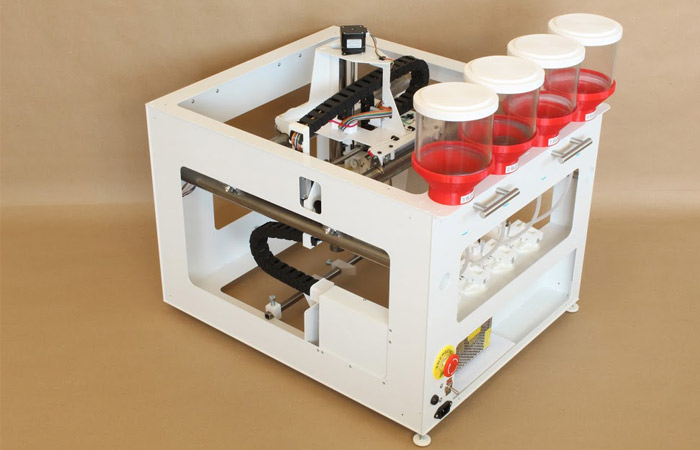

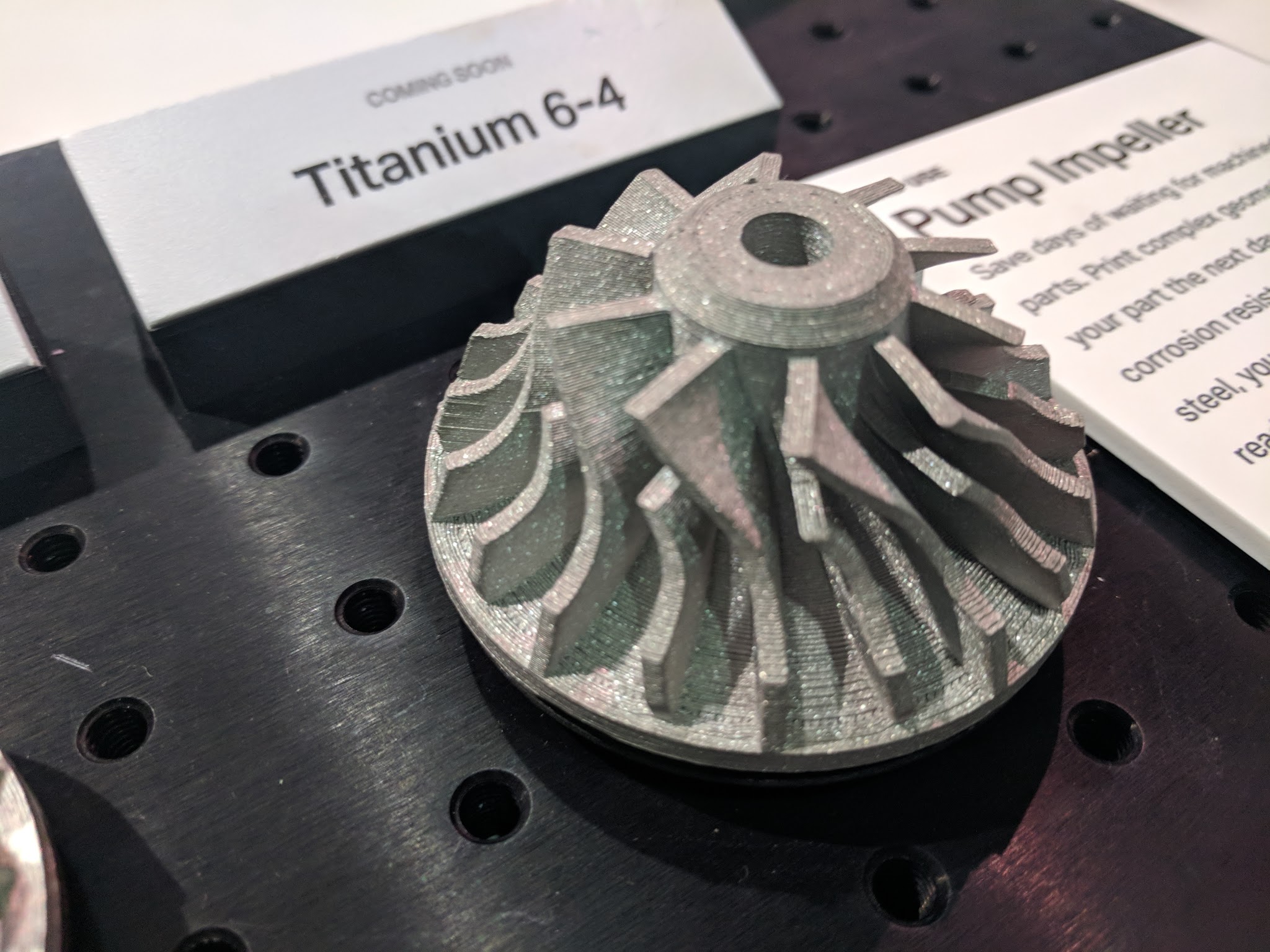

For anything else print with titanium aluminum kevlar or one of our 11 other materials to fit any functional application. Browser based desktop application with local storage and fully offline. 2 the printed part is then washed to remove some of the binder. As with any new piece of equipment it can often be difficult to know how quickly it will pay itself off.

1 metal powder bound in plastic filament is 3d printed in the shape of your design. The metal x is based on our fourth generation composite 3d printing technology and is a brand new kind of 3d printer. Now the final parts are ready for use. By printing metal powder bound in a plastic matrix weve eliminated the safety risks associated with traditional metal 3d printing while enabling new features like closed cell infill for.

Find out how much a metal 3d printer costs by looking at some popular machines on the market. The cost includes the machine the wash 1 and a sinter 1.

/cdn.vox-cdn.com/uploads/chorus_image/image/54468897/studio_hero.0.jpg)