Solidworks Scan To 3d Cost

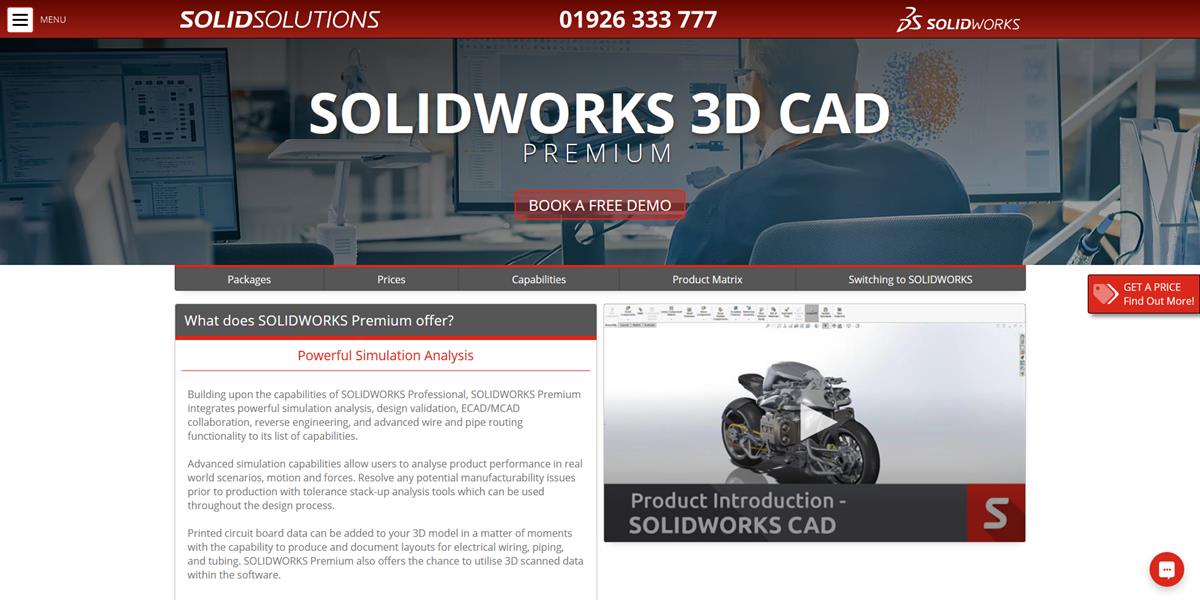

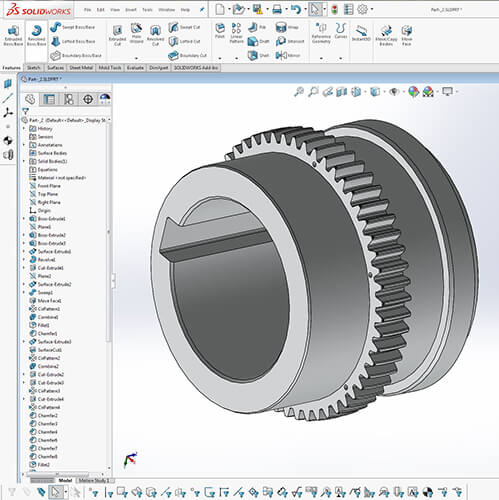

Whether you just create 3d models or you need to design a product from concept to manufacturing solidworks will have what you need.

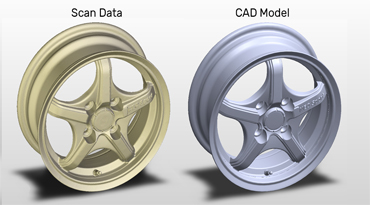

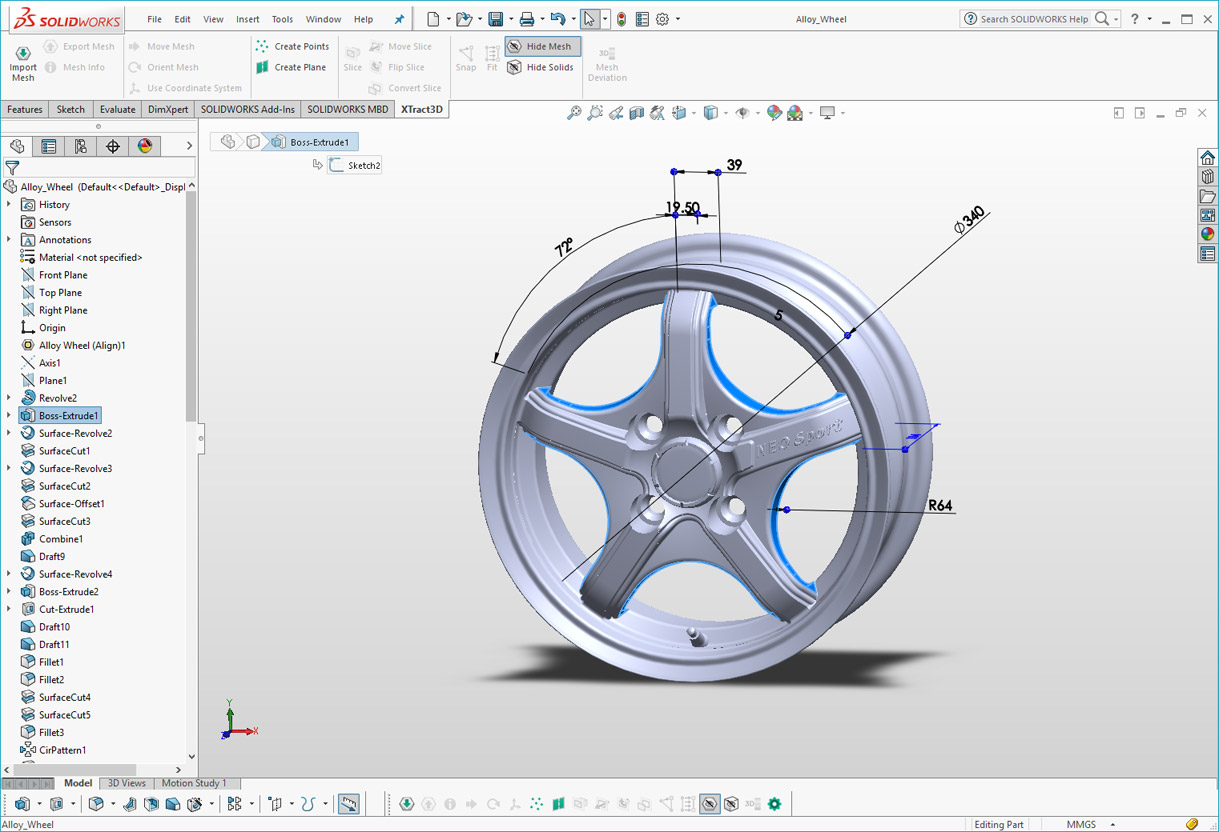

Solidworks scan to 3d cost. Scan to 3d is good for this as well it handles the point cloud data from the next engine scanner well but as its only available as part of premium and well premium is a big premium here in the uk i cant justify the cost put it another way for the difference in price i can buy the rapidworks module for the nextengine scanner for. Thanks for reading and remember. Step 1 import scan data into solidworks. Reduces time to market with the industrys fastest design from scan tools.

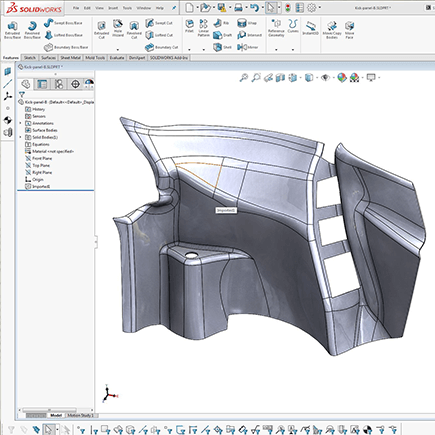

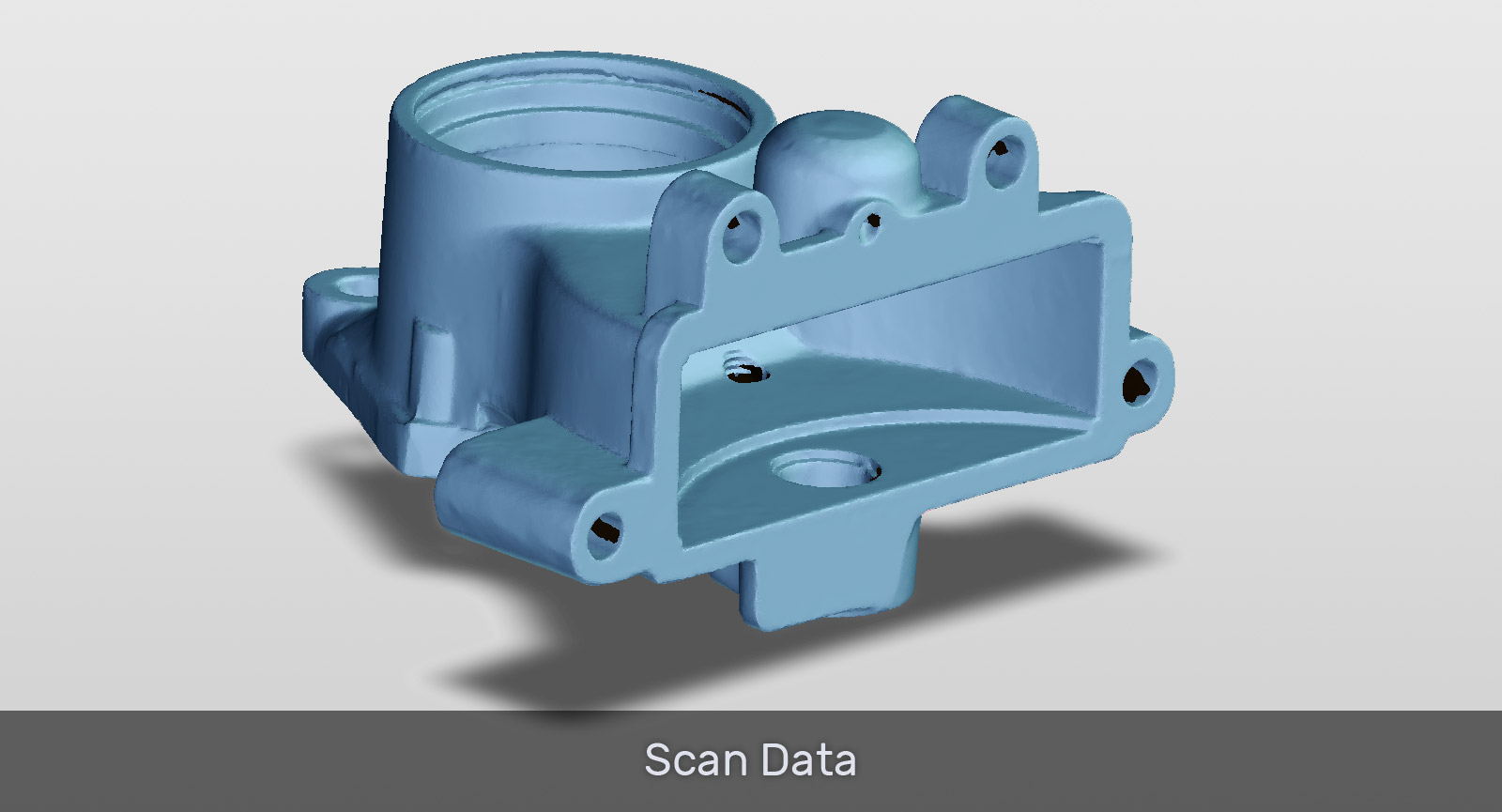

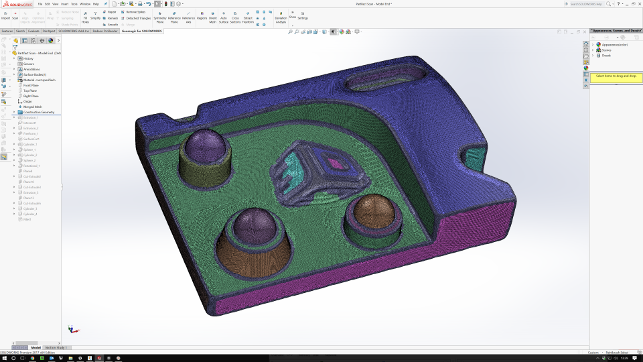

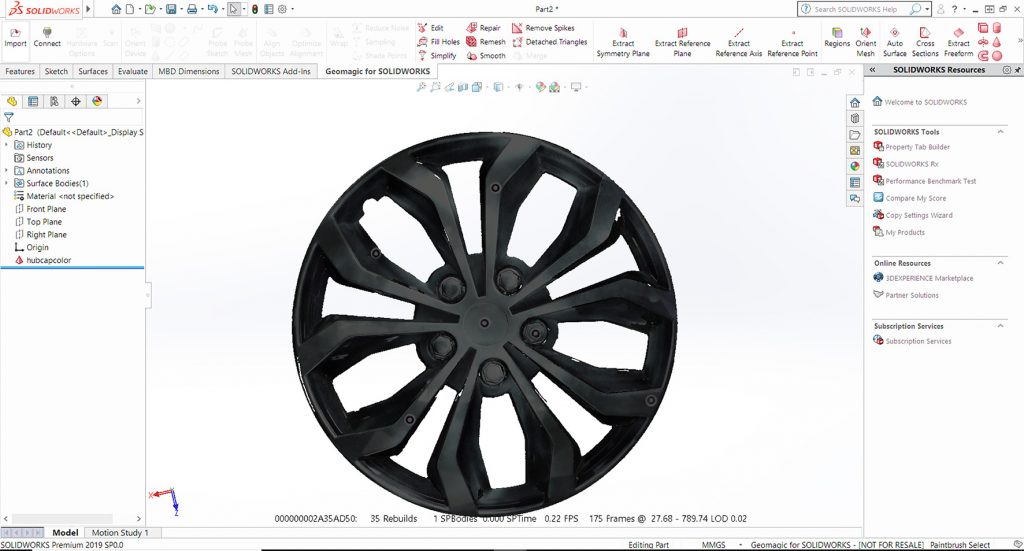

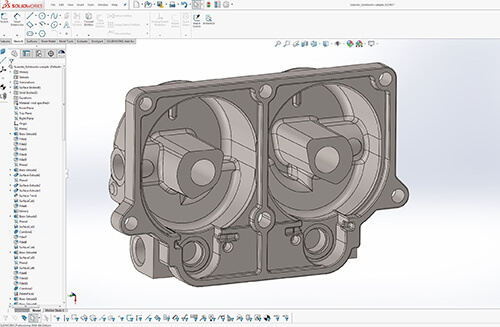

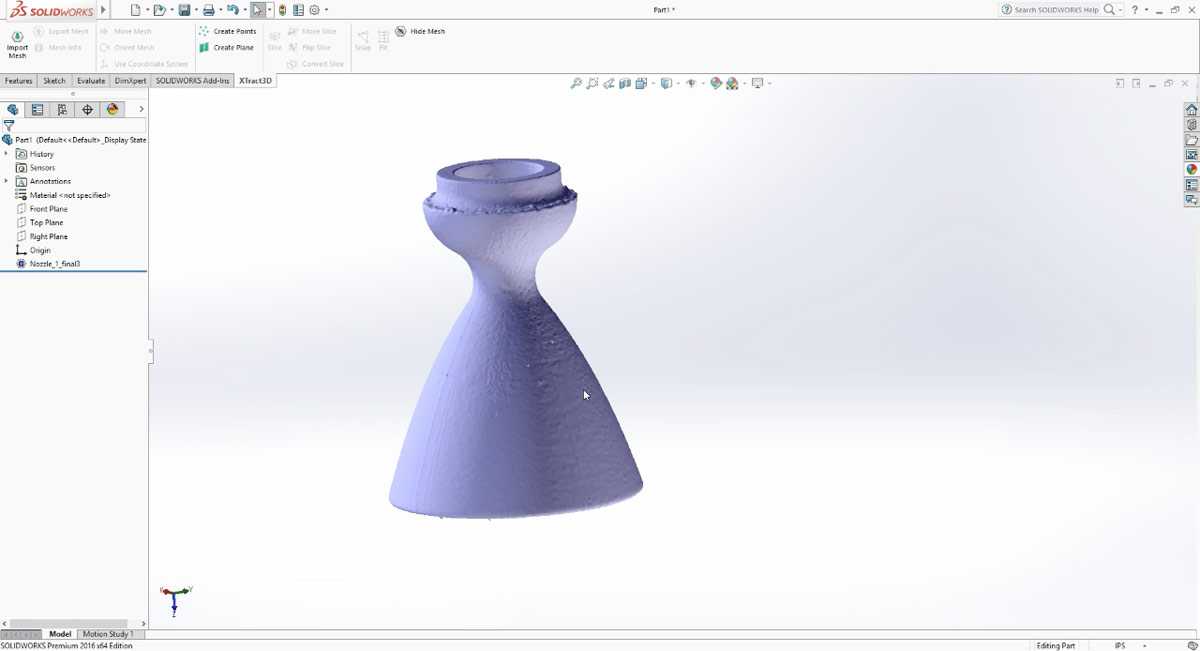

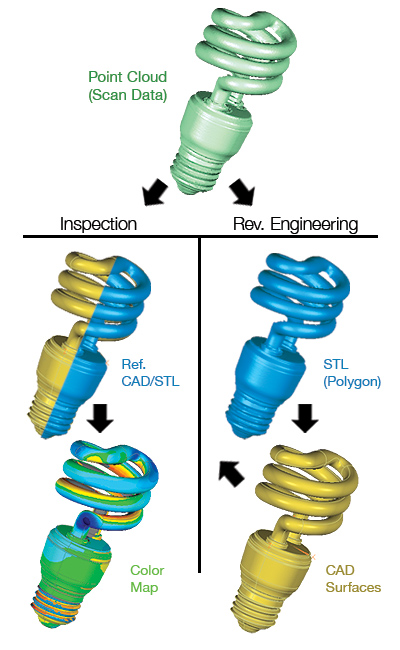

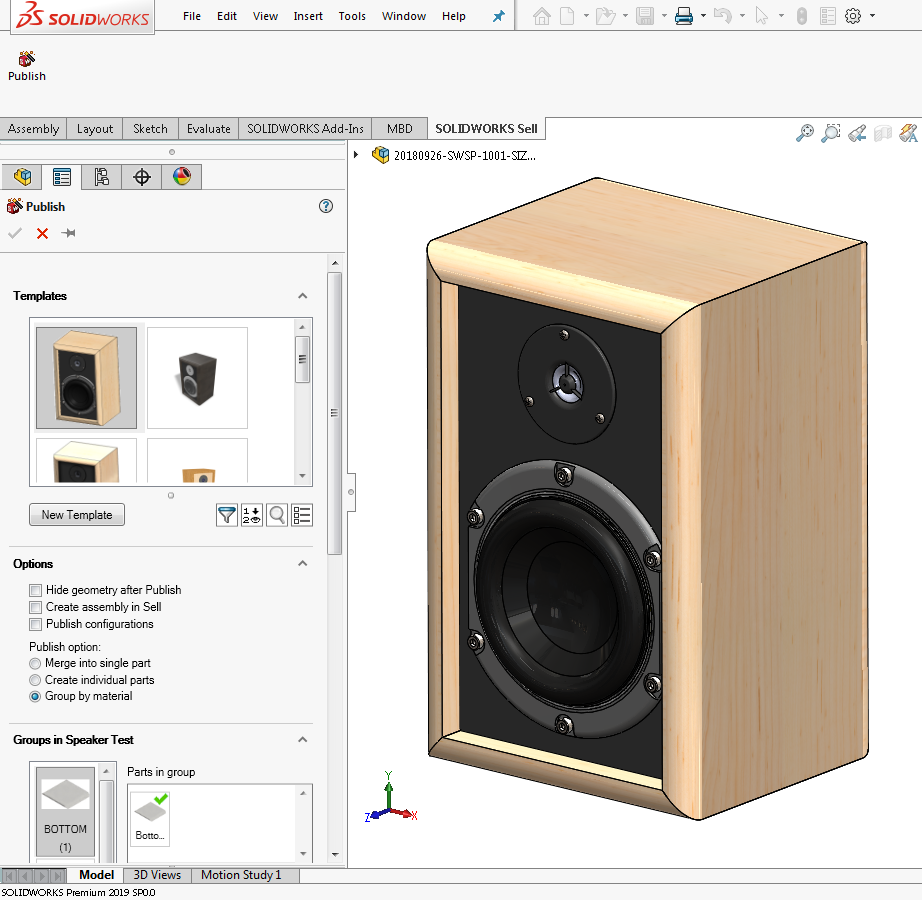

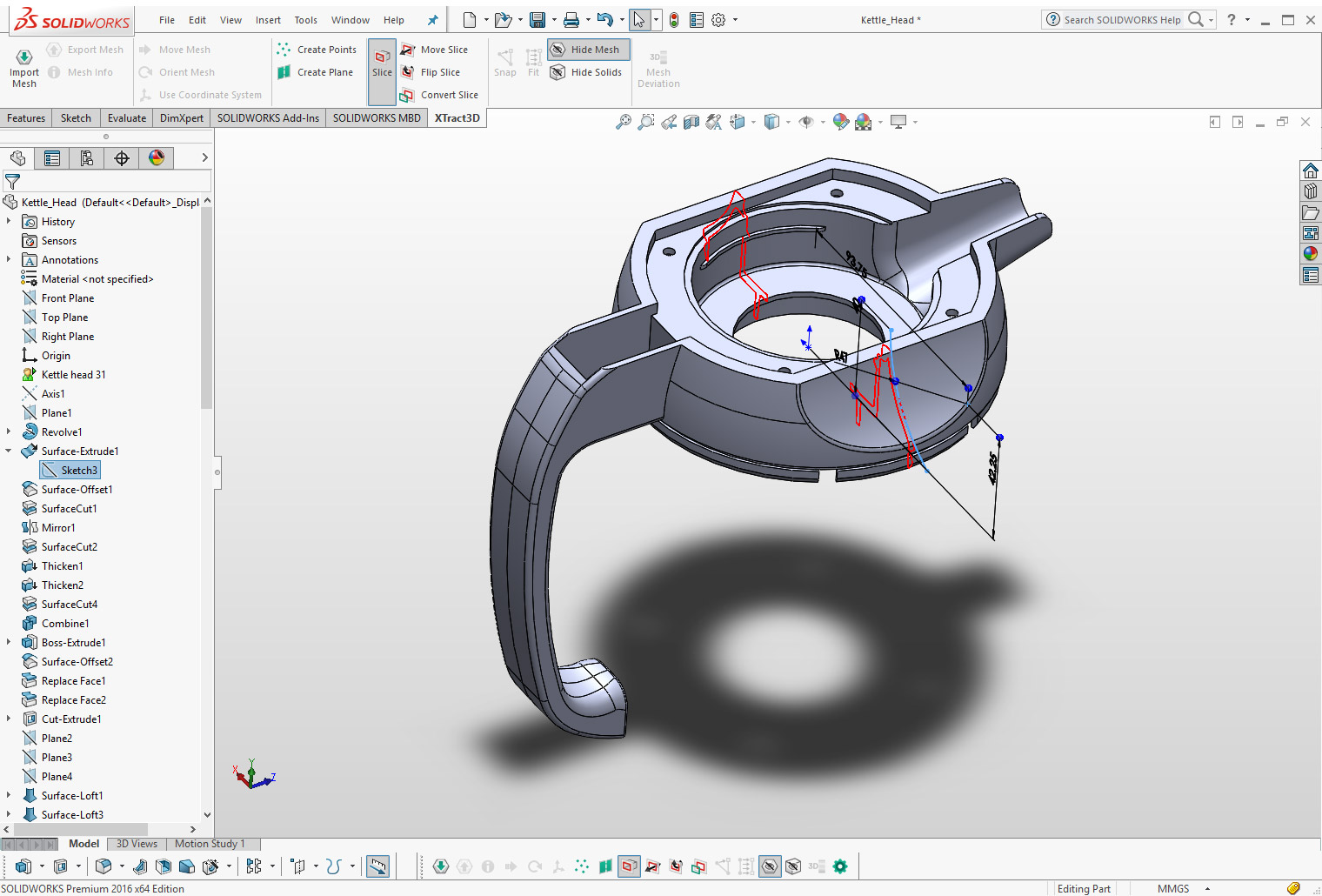

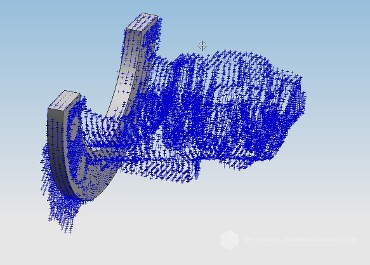

Start the reverse engineering process by importing the 3d mesh file obj ply or stl into solidworks. Combined a scanner with scanto3d and you have an affordable easy to use solution for capturing physical objects right from your desktop no more measuring. The bulk of the work went into creating a feature based solidworks model of high quality that the customer could use to create another mold. Allowing you to scan detailed parts and models and build your designs to match.

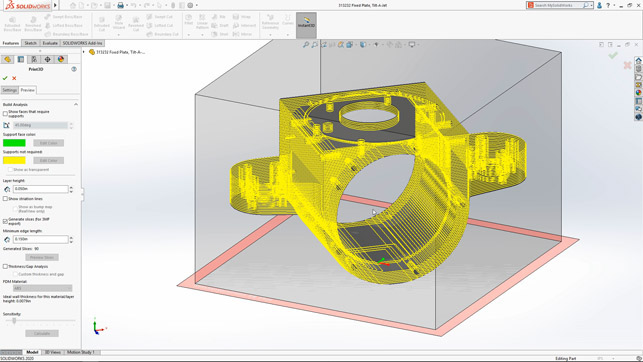

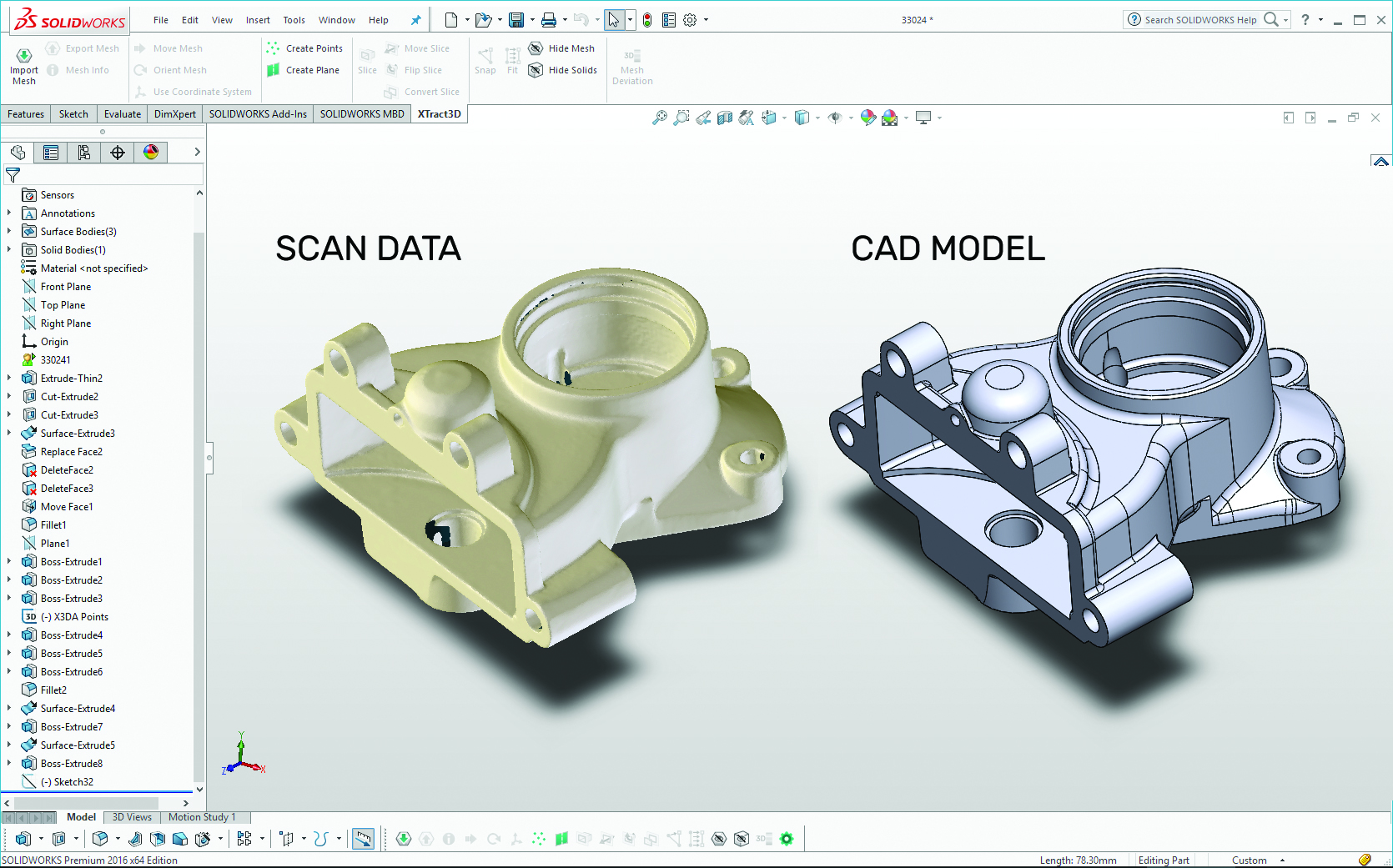

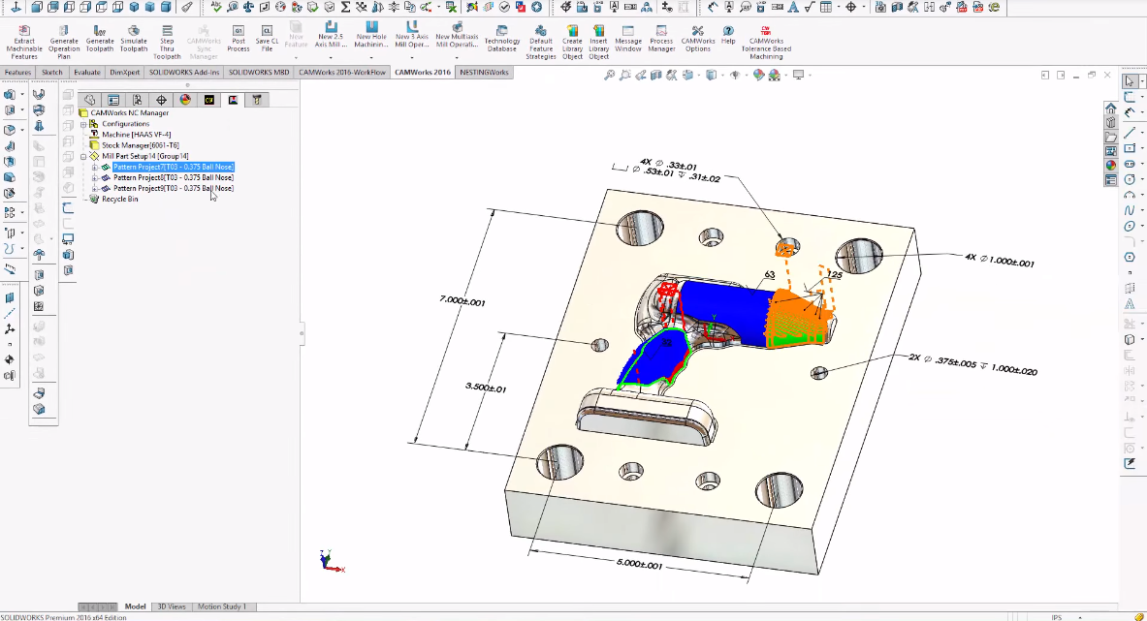

This happens before the scan data is imported into. The cost was in the 1000 range. Geomagic for solidworks is the industrys most complete integrated scan to solidworks model solution. Solidworks is a very powerful cad package that can be customised to suit your specific requirements.

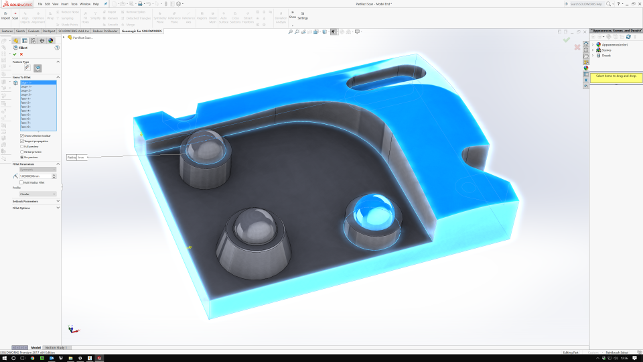

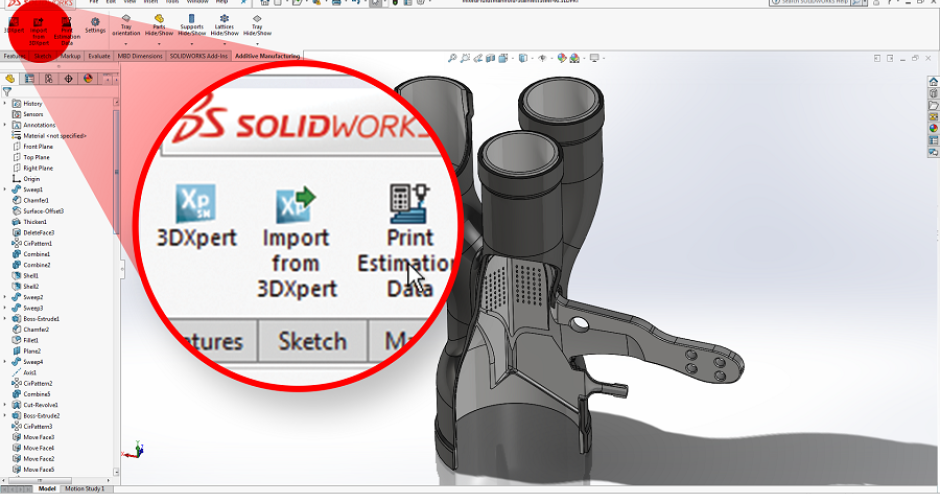

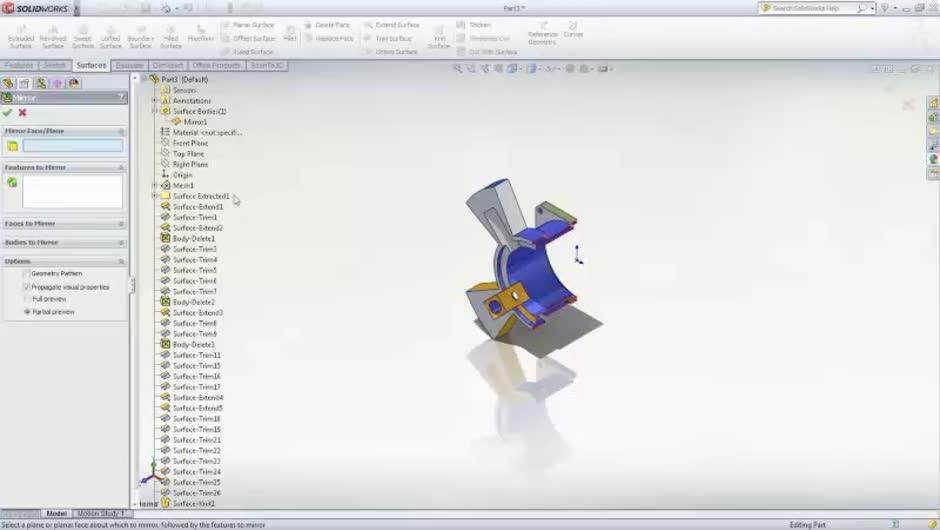

Design x works seamlessly with your solidworks design process. Delivers the fastest path from 3d scan data to a feature based cad model. Using the solidworks softwares scanto3d functionality you can open scan data from any scanner mesh or point cloud files or curve data from mathematics software prepare the data then convert it into a surface or solid model. Reduce the time required to build complex 3d models of real world objects by directly scanning or importing scan data into solidworks.

Due to the complex shape of the casting the 3d laser scanning was only 20 of the cost. The cleanup process the task of deleting unwanted scan data hole filling aligning and merging of 3d scans normally takes place inside the 3d scanning software that comes with the 3d scanner. Vxinspect is a dimensional inspection software for quality control and allows direct measurement comparison with cad models to better understand scancad deviations. For more information on vxinspect or other 3d scanning solution check back into catis tech notes for future blogs.